Free Shipping Australia wide on orders over $100

Usually ready in 24 hours

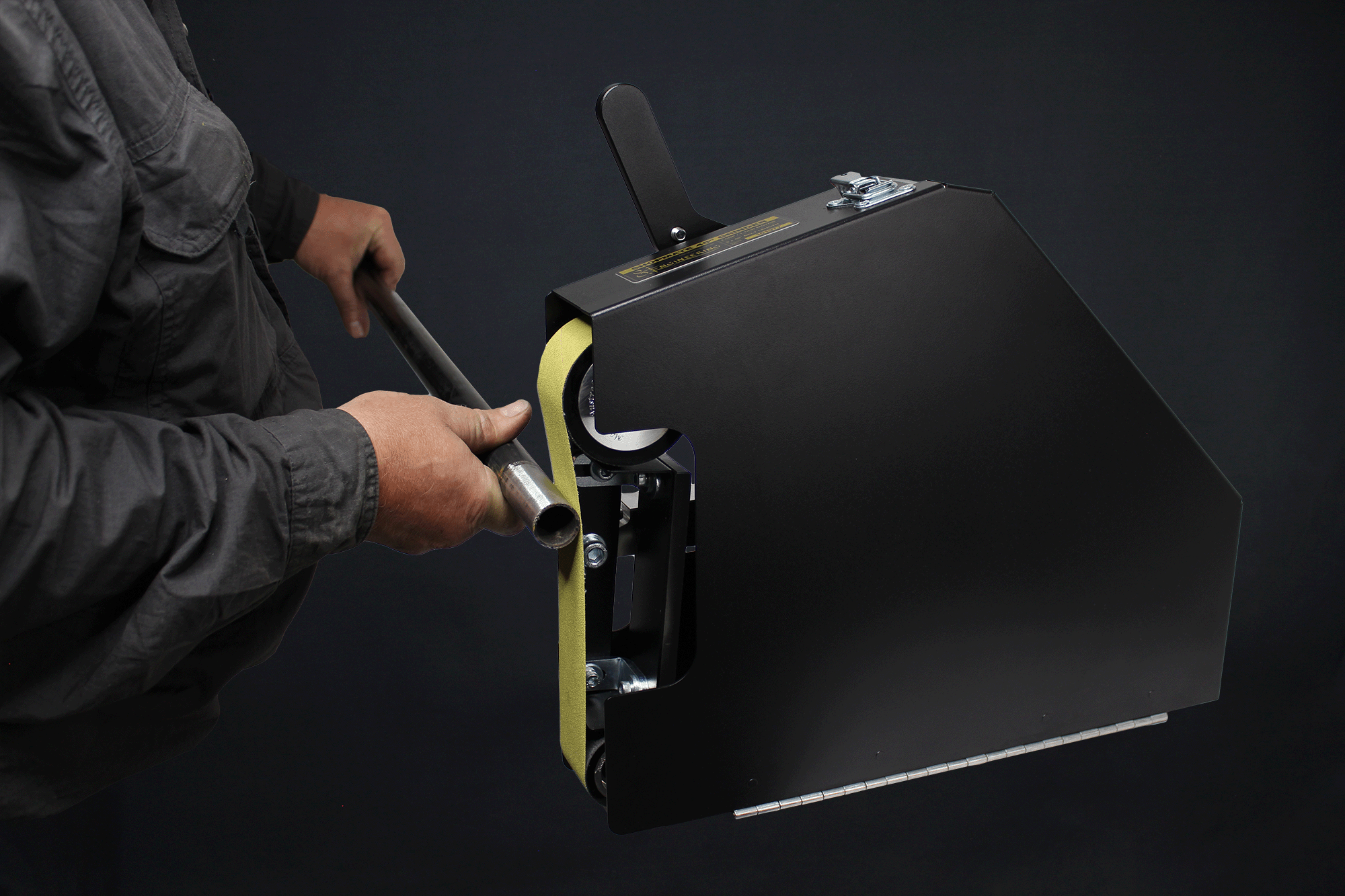

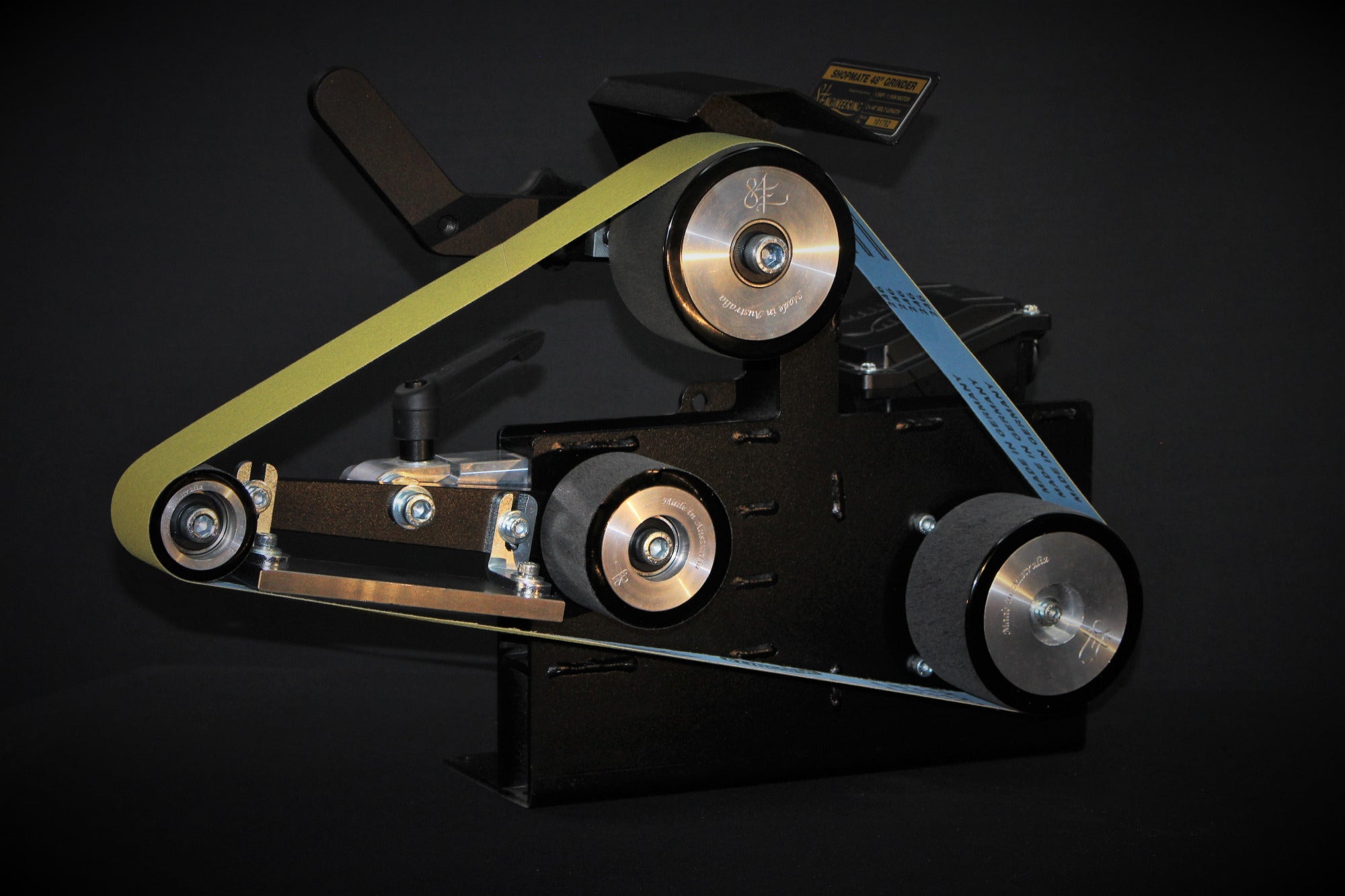

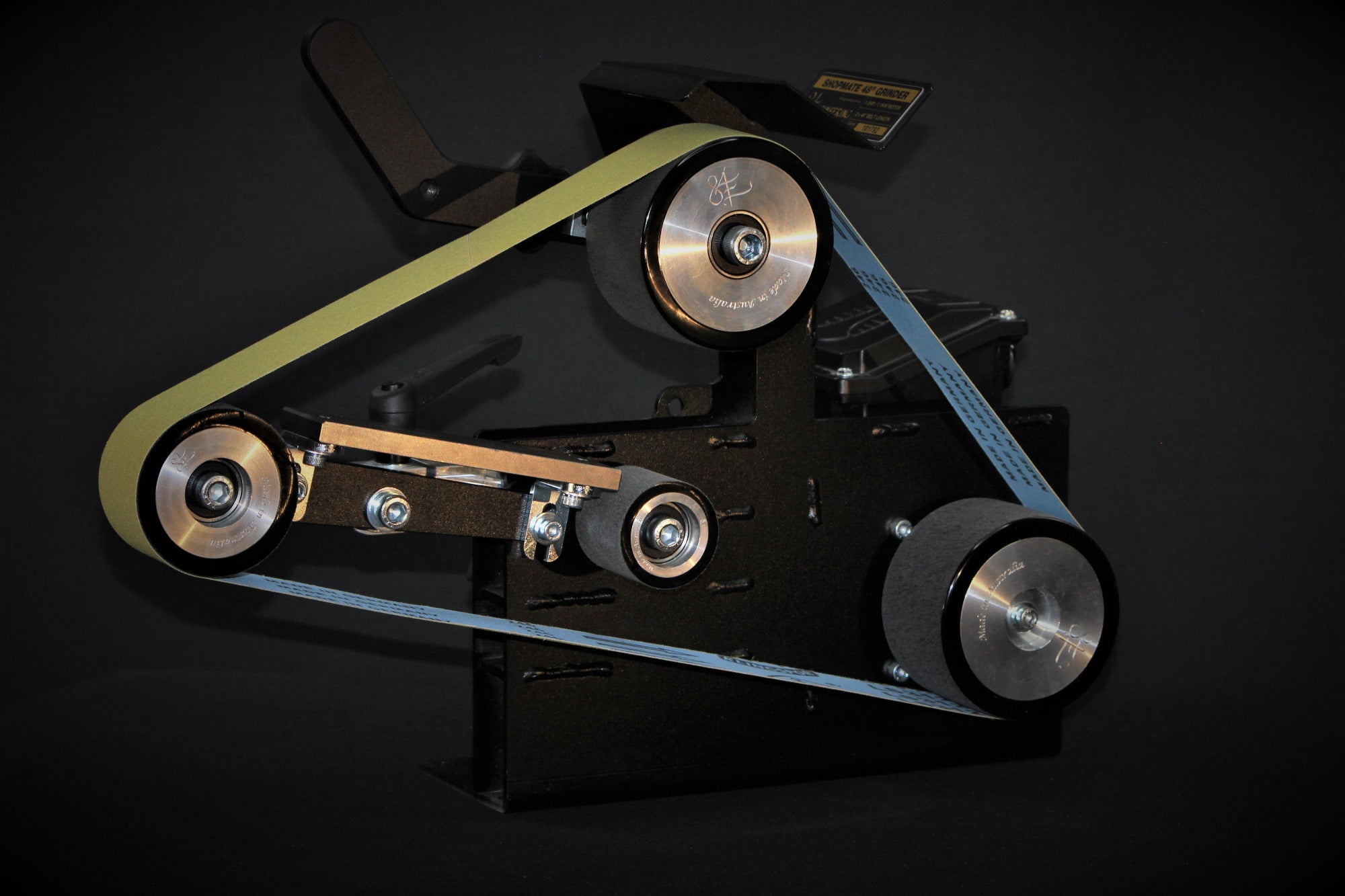

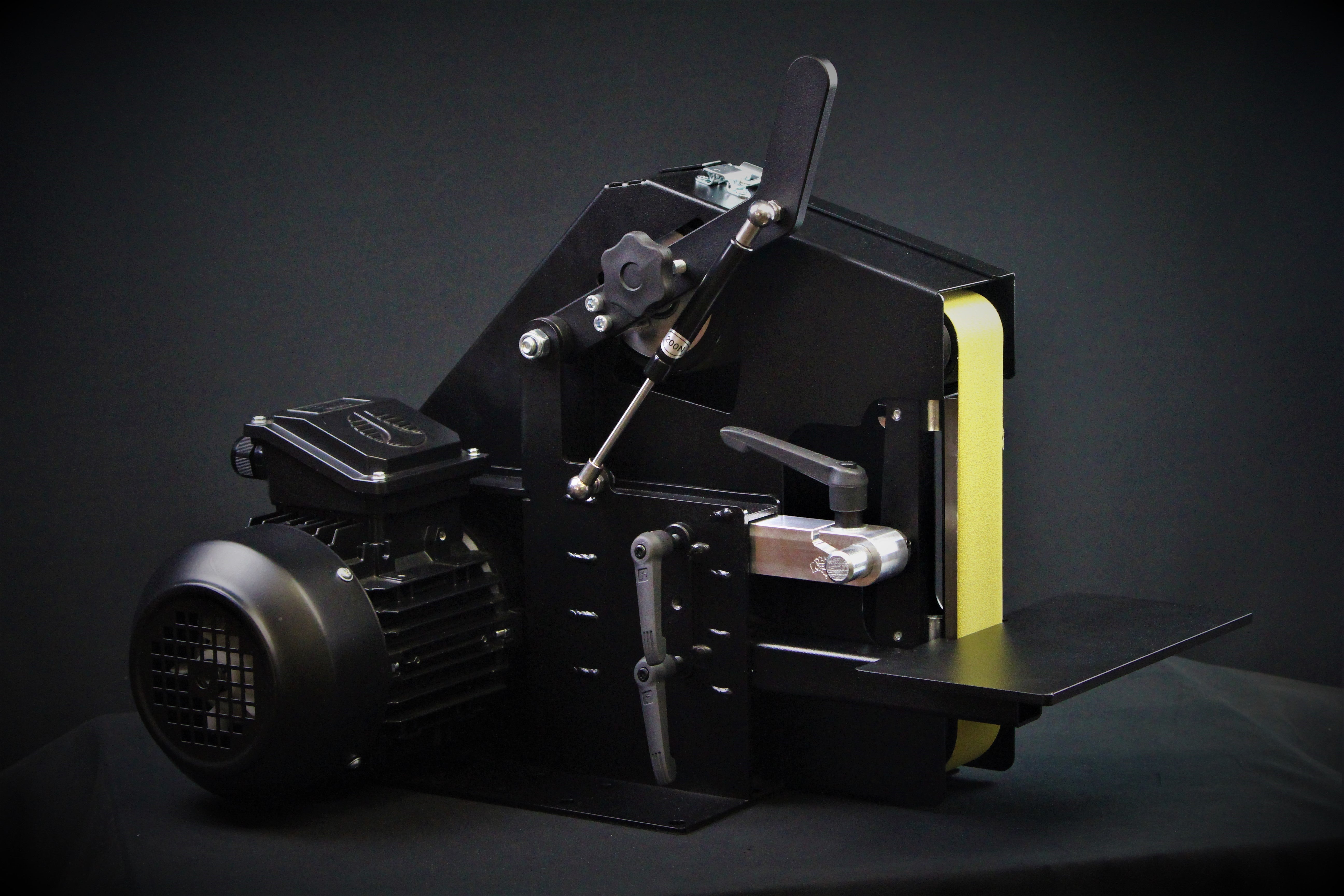

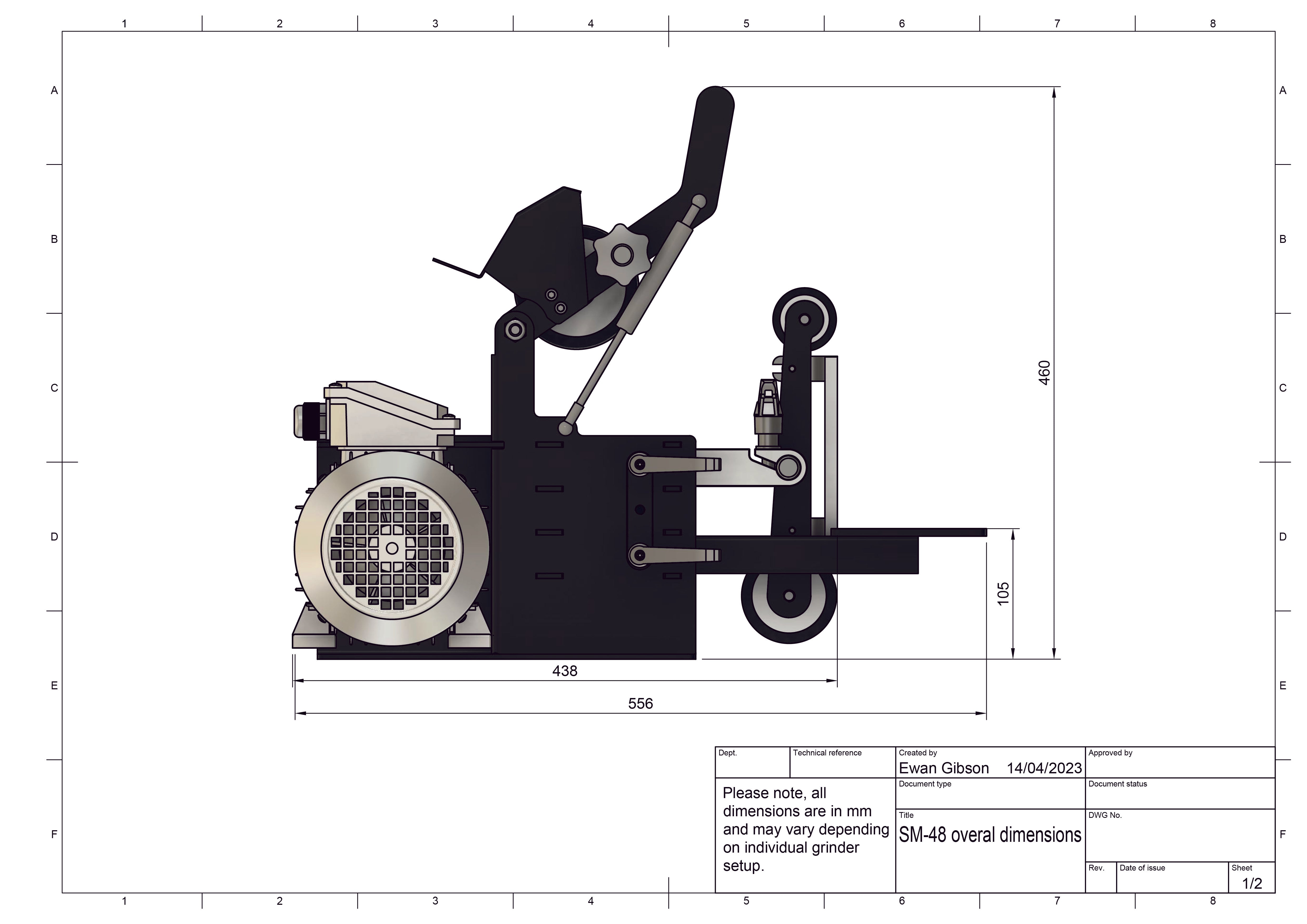

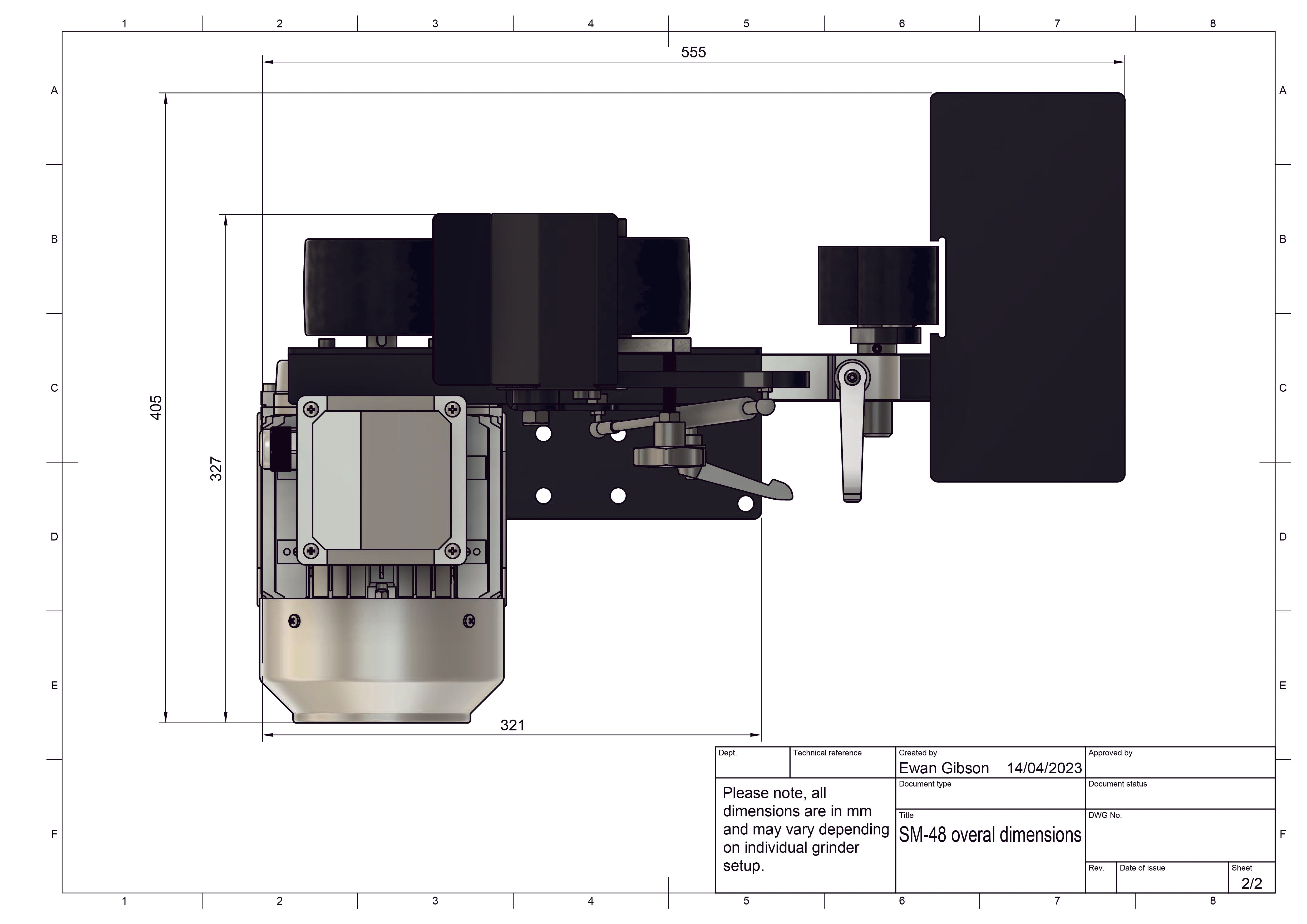

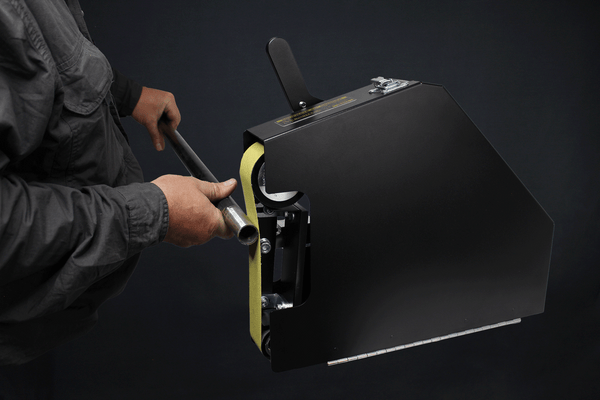

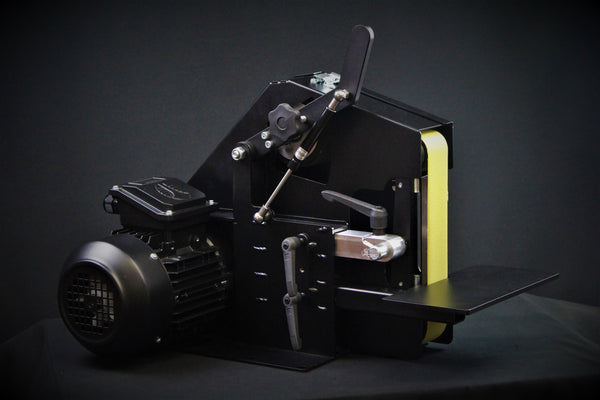

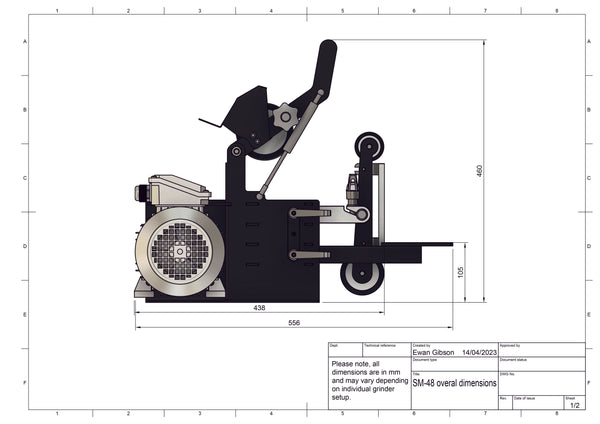

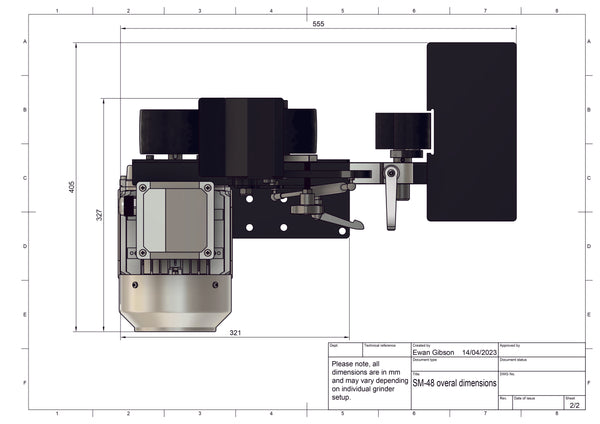

The Shop Mate 48” belt grinder linisher is the most compact belt grinder in the 84 Engineering line-up, but don’t let it’s size fool you! Equipped with an industrial 1.1kw (1.5hp) 3 phase motor, variable speed controller, capability to run from 1/4" up to a 10” contact wheel as well as being fully compatible with our entire range of accessories – the Shop Mate offers the versatility of the larger 72” belt grinders / linishers on the market - without the footprint.

The Shop Mate 48" belt grinder will plug into any standard 240v power socket. The included Variable Frequency Drive (VFD) / speed controller converts power to a 3-phase signal, driving the 1.1kw motor. This setup allows you to dial in the belt speed anywhere from 0 – 4800 fpm and provides maximum motor torque even at low RPM. The VFD will automatically ramp up power when under load to maintain belt speed.

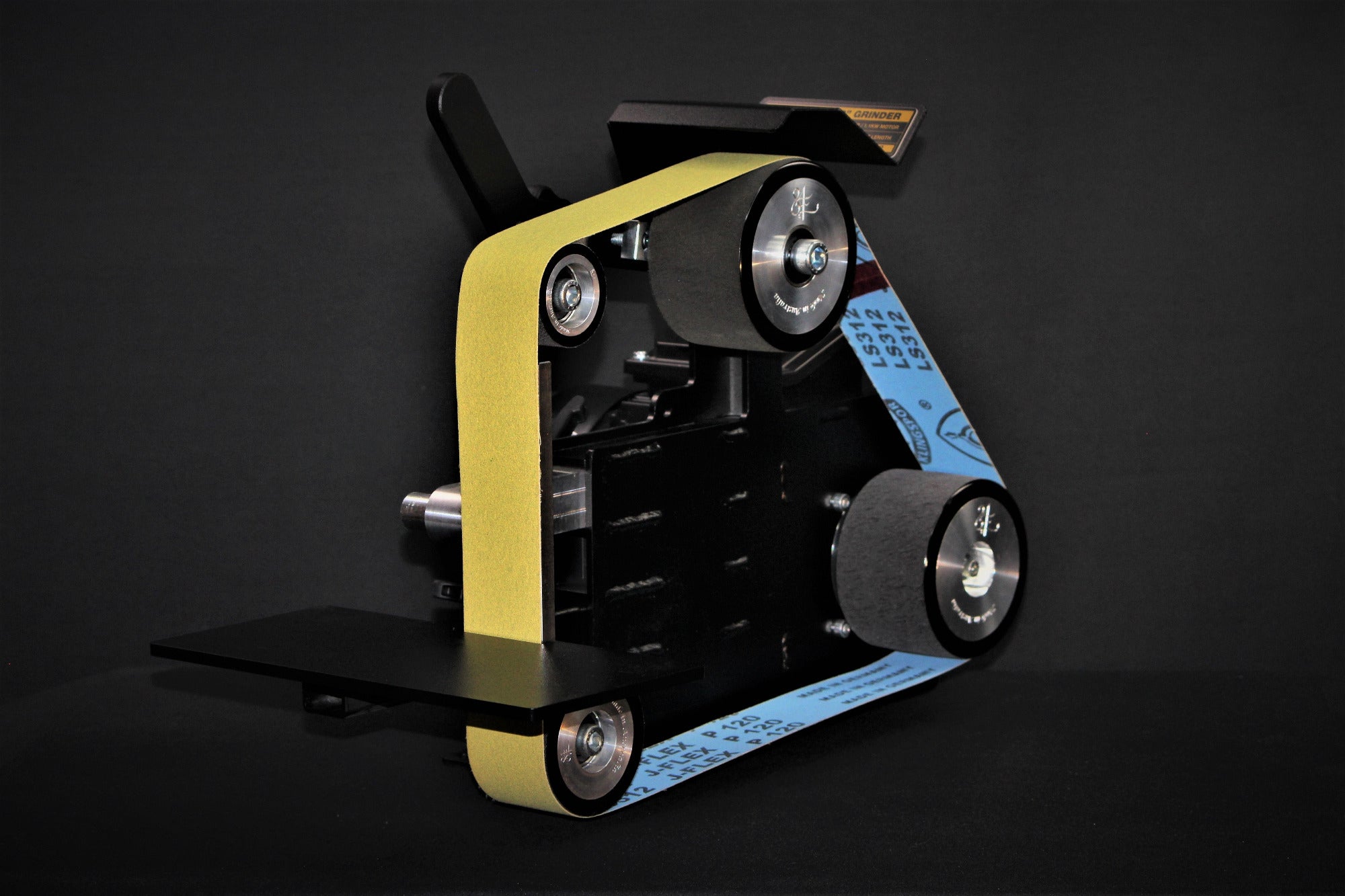

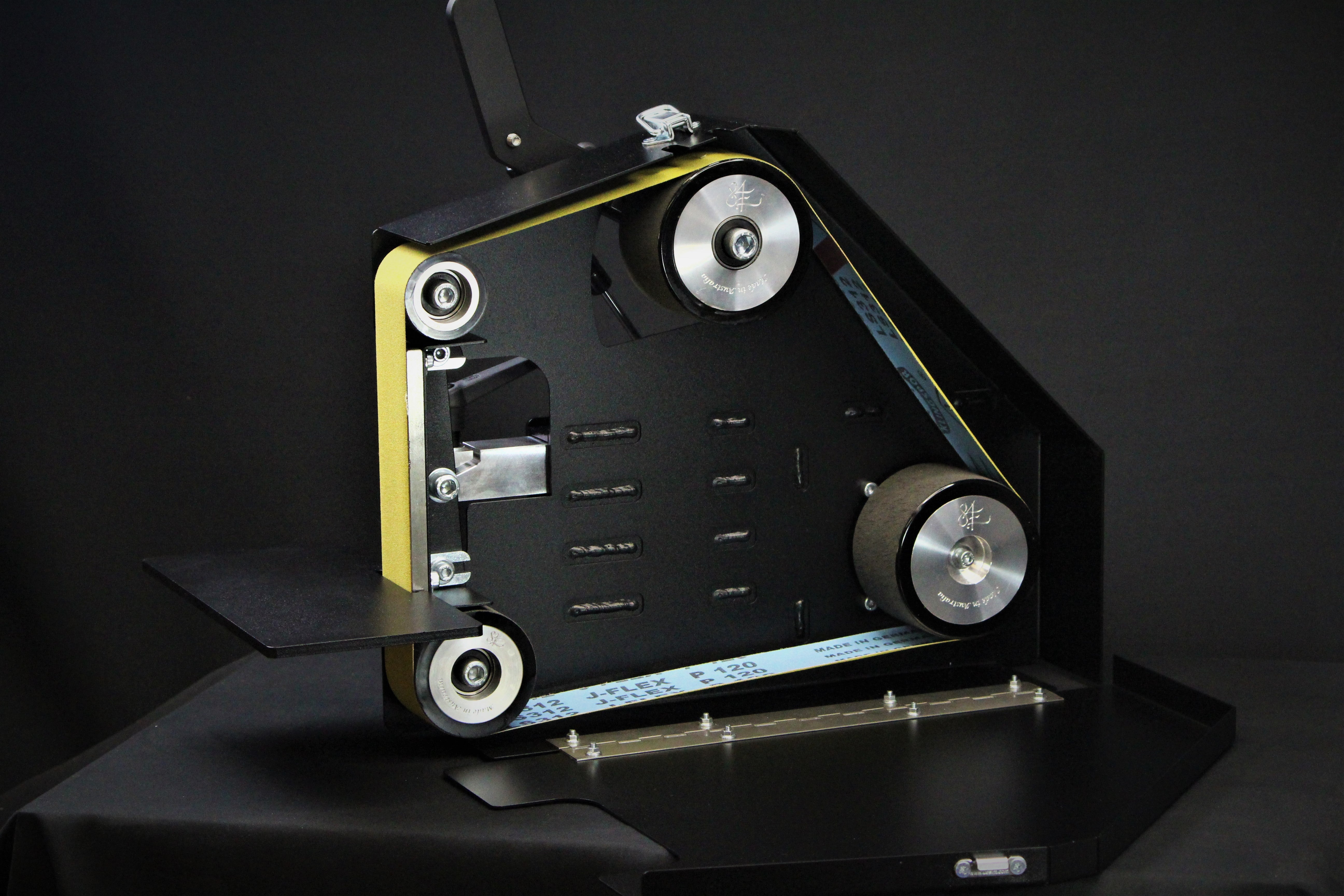

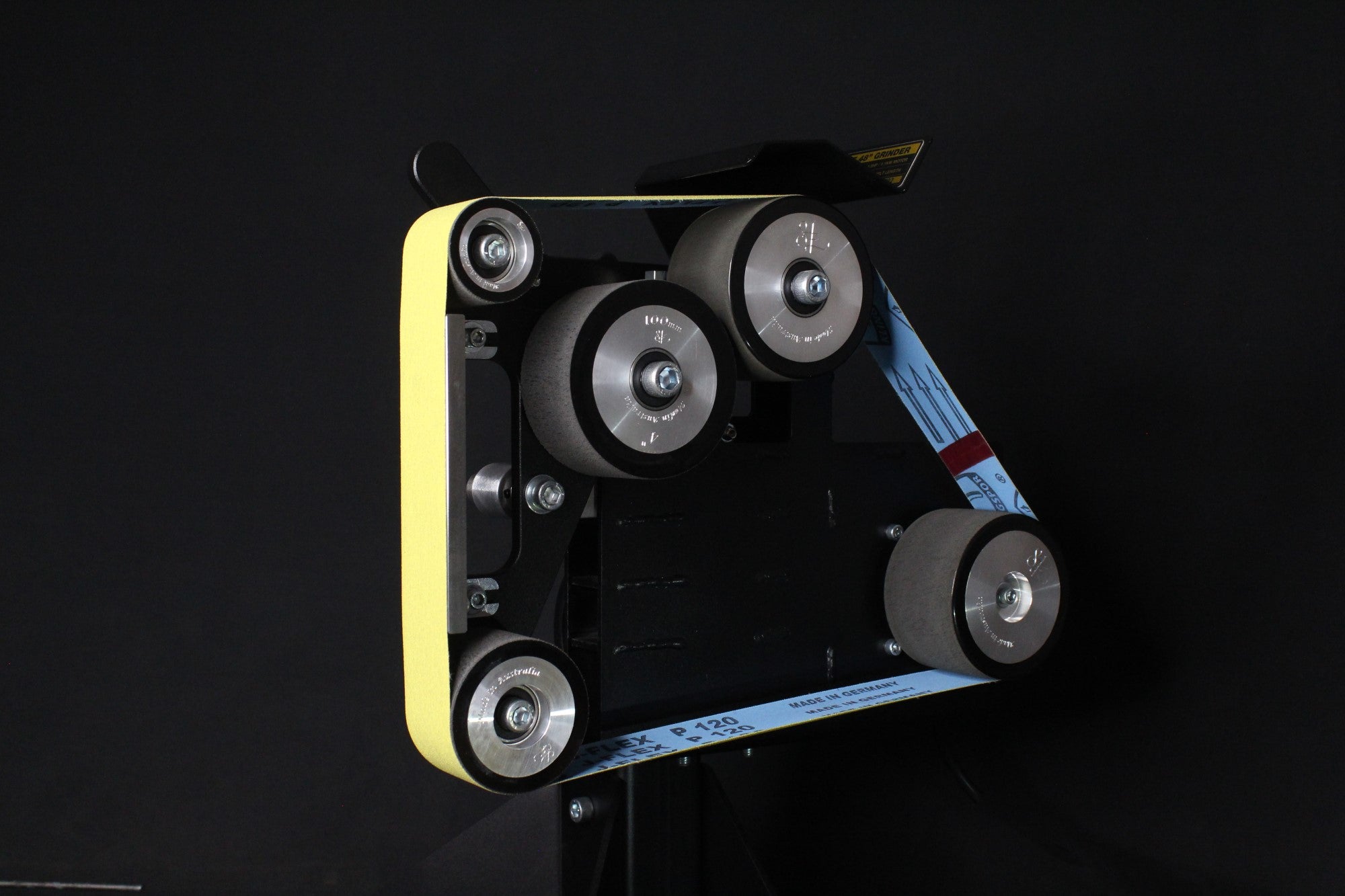

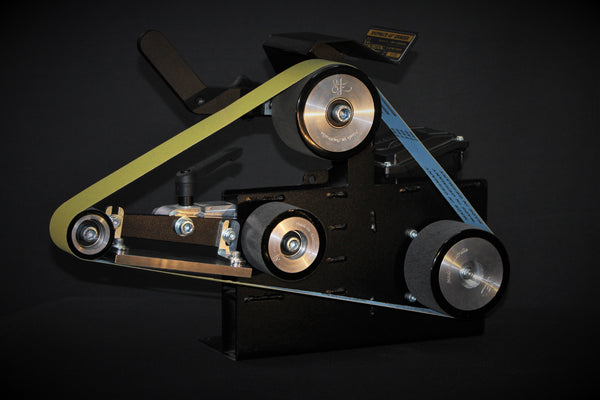

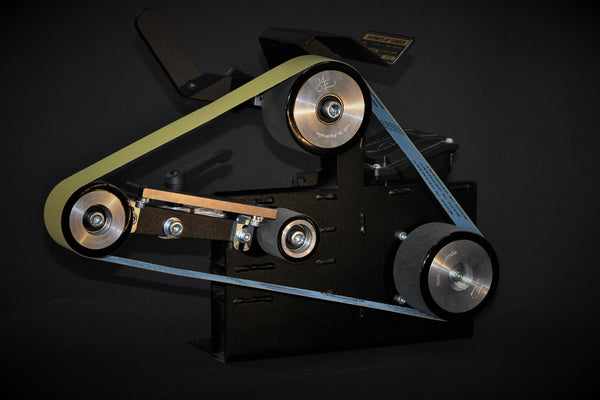

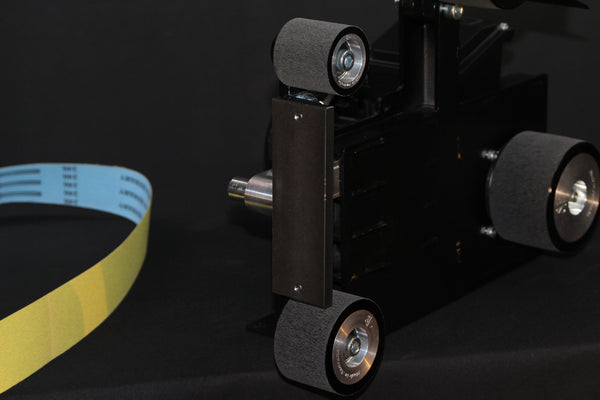

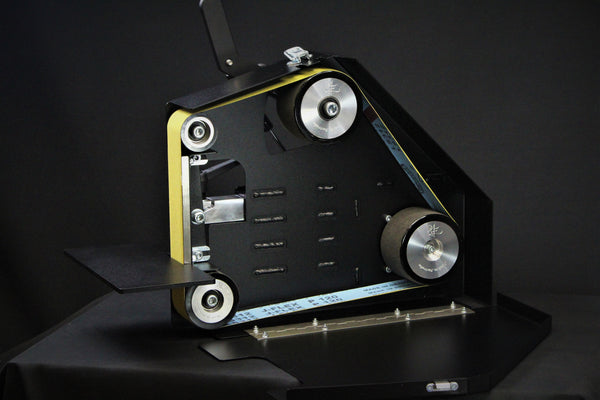

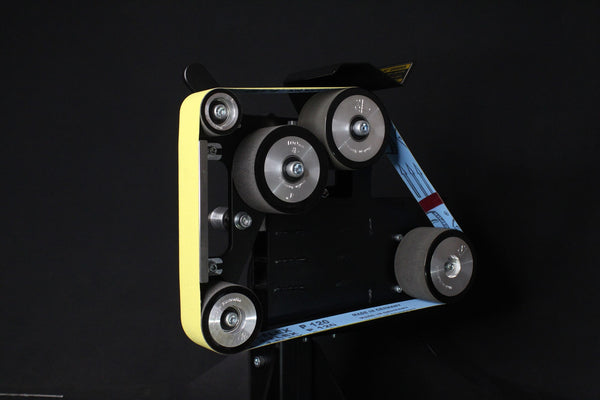

The Shop Mate is equipped with a multi-function rotating platen – giving you the option of a 150mm flat platen, 2” contact wheel, 3” contact wheel and slack belt out of the box. Changing between these configurations is as simple as loosening the locking handle and spinning the platen – you don’t even have to remove the belt!

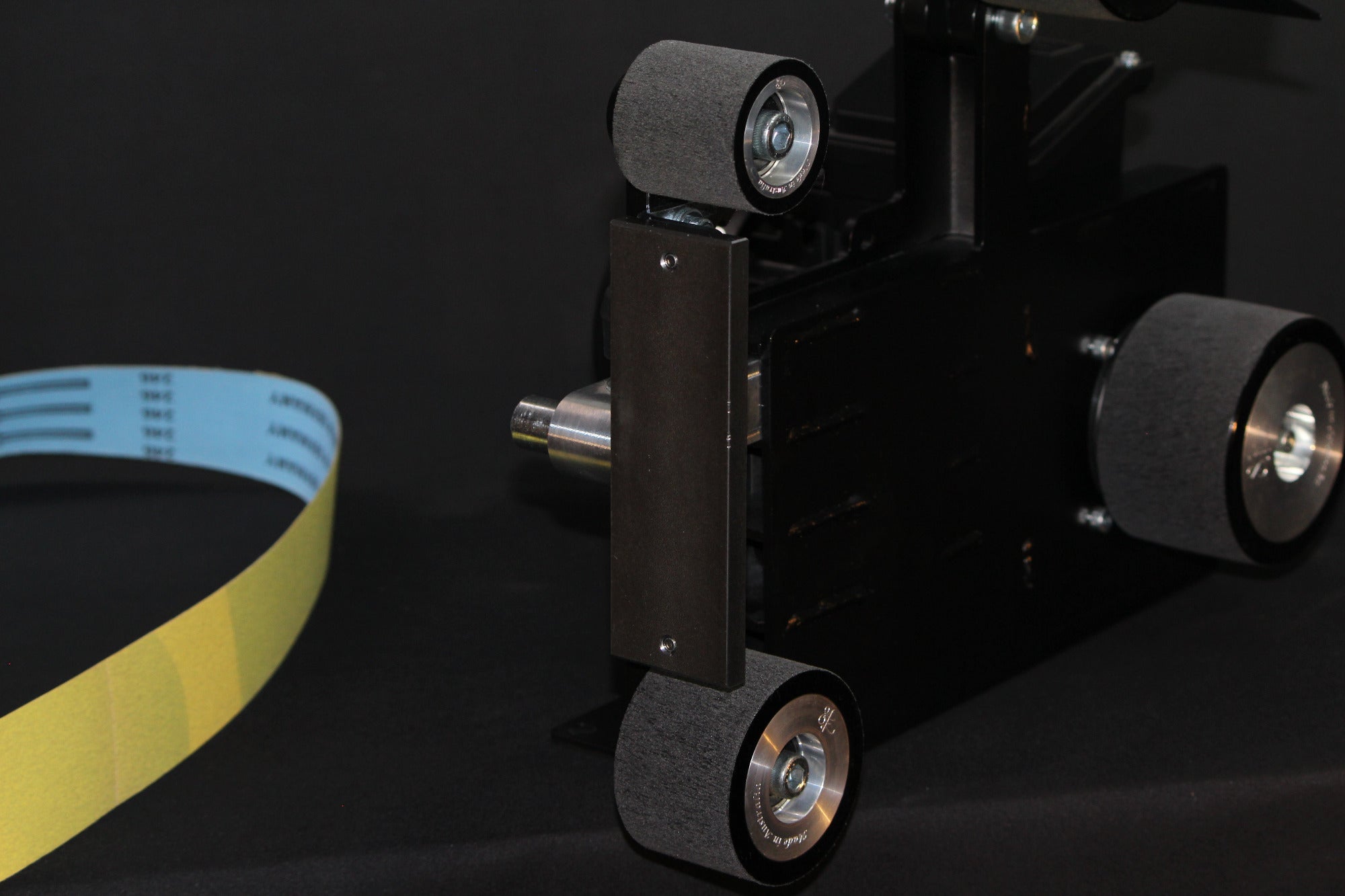

You can also opt to include our Tri platen, with more clearance on the left side and a 4" contact wheel! This option will ship without the 2 wheel platen or regular platen arm. To use small wheels with this option you will need either a standard length arm or small wheel arm.

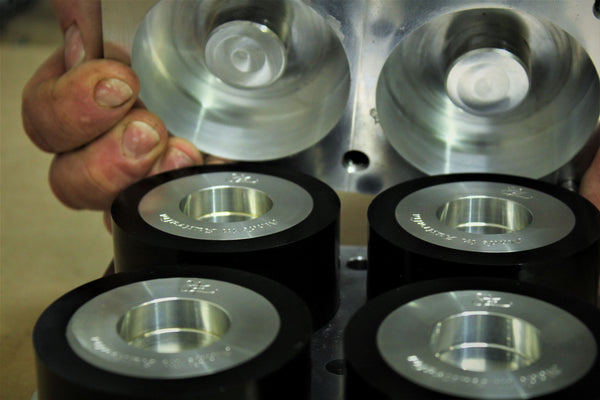

All wheels on the Shop Mate 48" belt grinder are precision CNC machined from 6061 billet aluminium and coated in our newly formulated abrasion-resistant Urethane rubber. Not only does this provide excellent drive wheel traction (the belt will never slip, regardless of how much pressure you apply), but makes for quieter operation and a superior grinding experience. The rubberised wheels even out belt discrepancies meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit grinding belts / abrasives.

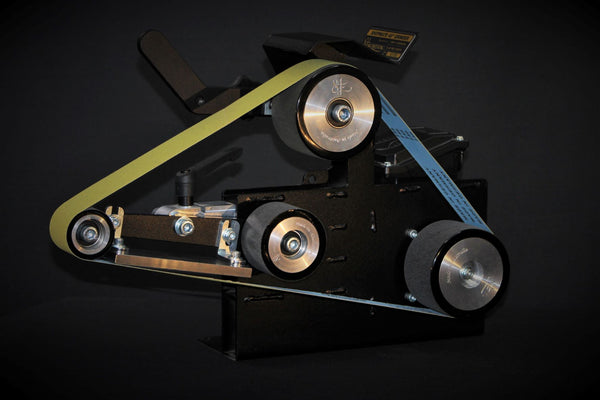

The flat-plane tracking mechanism offers increased tracking stability and ease of adjustment over many other options available on the market. The tracking is set-and-forget - just dial in tracking with the twist of a knob and it will remain true even under heavy belt load. The flat-plane tracking also allows for minimal crown/curvature of the tracking wheel meaning your j-flex and other lighter grinding belts / abrasives won't deform over time.

In the box is a fully powder-coated and assembled grinder, a fixed work rest, a tooling arm and a rotating platen – everything you need to complete most workshop fabrication tasks, wood / metal-working projects and knife shaping, sharpening and stock removal work. If you need your grinder for specific applications or simply require more versatility, a large range of compatible attachments, work rests and contact wheels are available.

• 2 × 48” belt length

• 1.1kw (1.5hp) 2 pole motor with 4” drive wheel

• 0 – 4800 surface feet per minute belt speed

• 6” platen

• 4 way rotating platen

• Slack belt

• 2” and 3” contact wheels

• Rubber coated wheels for smooth performance and great belt traction

• Flat plane belt tracking for accurate belt alignment

• Fully welded frame

• 3 arm slots

• Fixed work rest

• Platen arm also accepts small wheels

• Protective spark guard

• Flips from vertical to horizontal with bench or pedestal stand (sold separately)

• Made in Australia

- Shop Mate 48 grinder body

- Rotating platen

- Fixed work rest

- Pre-wired 1.5hp motor and VFD

- 10% discount code to use on belt purchases for life.

Our on-line store is open 24/7 and we ship Monday through Friday, excluding some holidays. Orders received for products without shipping restrictions on its product page will ship the following business day when received before 12:00 p.m. AEST. Orders in high demand will have an estimated production time listed on its product page and will ship according to the date listed.

I love this machine i installed it last year and I am so pleased with.

Should have made the decision years ago.

Really appreciated Ewan’s generosity with his time with a complete beginner. Spent a long time with me over the phone explaining everything and never over-selling. Greatly appreciated!

Outstanding product and customer service. Highly recommend.

Bought the shopmate 48 to complete my workshop set up and it’s everything I knew it would be. Such a lovely piece of kit with the attachments I feel there’s nothing I won’t be able to finish now.

Arrived within 4 days , easy to set up, and precision made 10/10.

Variable Frequency Drive (VFD) allows for fine control over belt speed, from 0-4800fpm (0-24m/s) with minimal torque loss

All wheels coated in house using a durable urethane rubber - great for belt traction, accurate tracking and quieter, smoother grinding

Rotating 4-in-1 platen allows you to easily change between 150mm flat platen, 2" contact wheel, 3" contact wheel and slack belt with the twist of a handle

DP Custom Knives

Have been a long time customer of 84 Engineering and every product I have purchased has been manufactured incredibly well with very high attention to detail. Customer service has also always been top notch. You will definitely be well looked after here.

Deathrig Fabrication

Amazing Aussie made products - used daily in my workshop. Quality second to none

Cafe Racer Garage

I have been using 84 Engineering belt grinders for many years, it's truly the one tool that gets the most use in my garage building motorcycles, It's one of those tools that you wonder how you ever did without! I highly recommend anyone working with steel have one! Dan - Cafe Race Garage -YouTube

Knife Maker

Our 84 Engineering machine is the best in our workshop and the best we've ever owned. Their service is second to none.

Follow us on social media for the latest news, deals and updates

© 2026, 84 Engineering Powered by Shopify