Free Shipping Australia wide on orders over $100

Usually ready in 24 hours

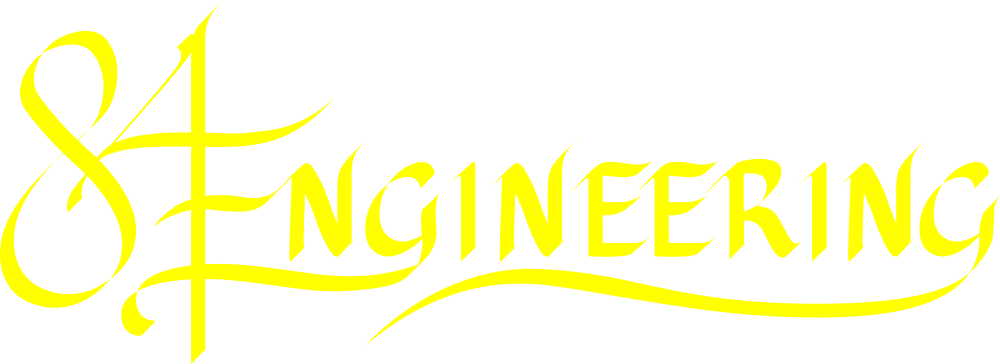

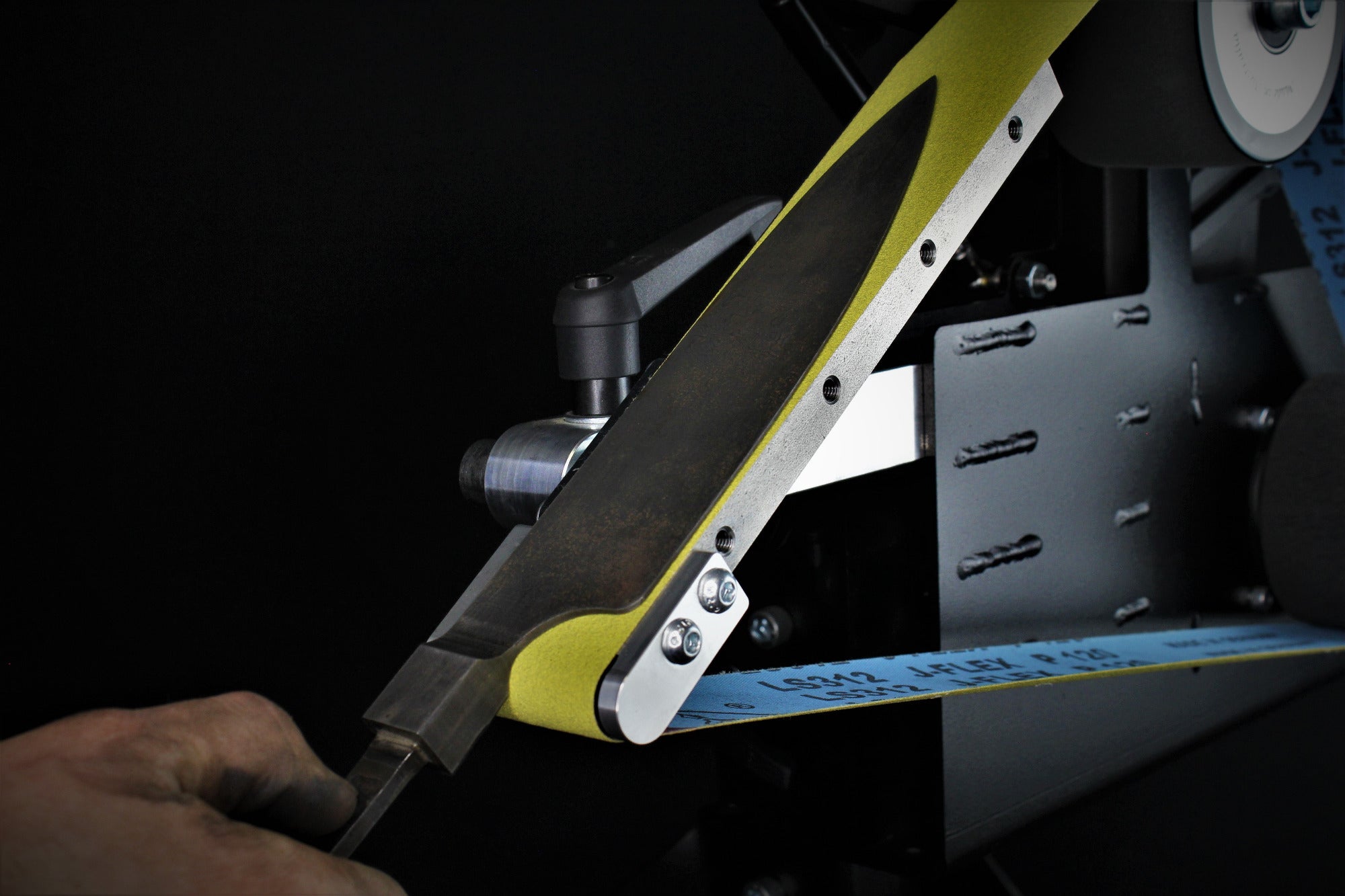

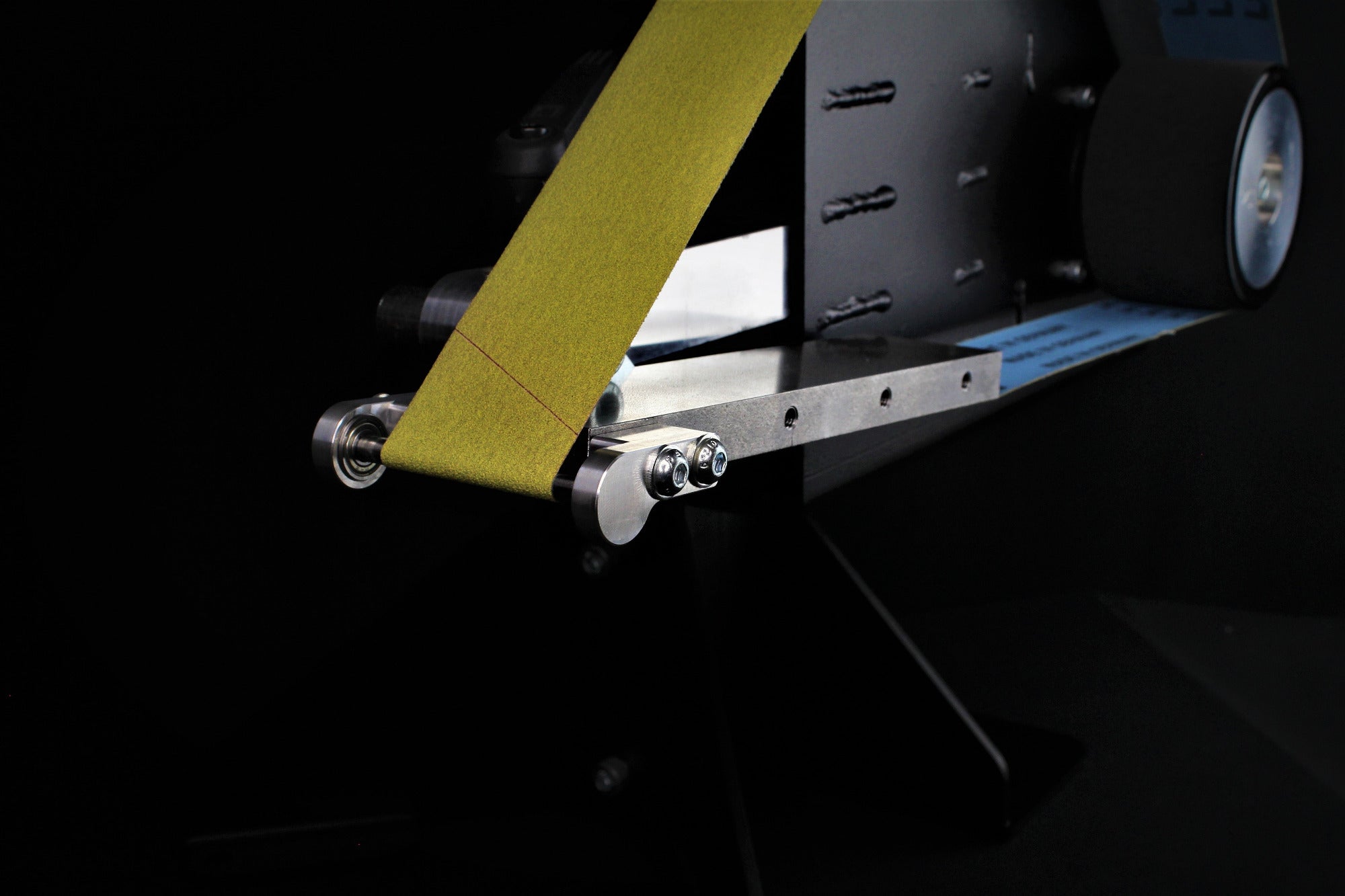

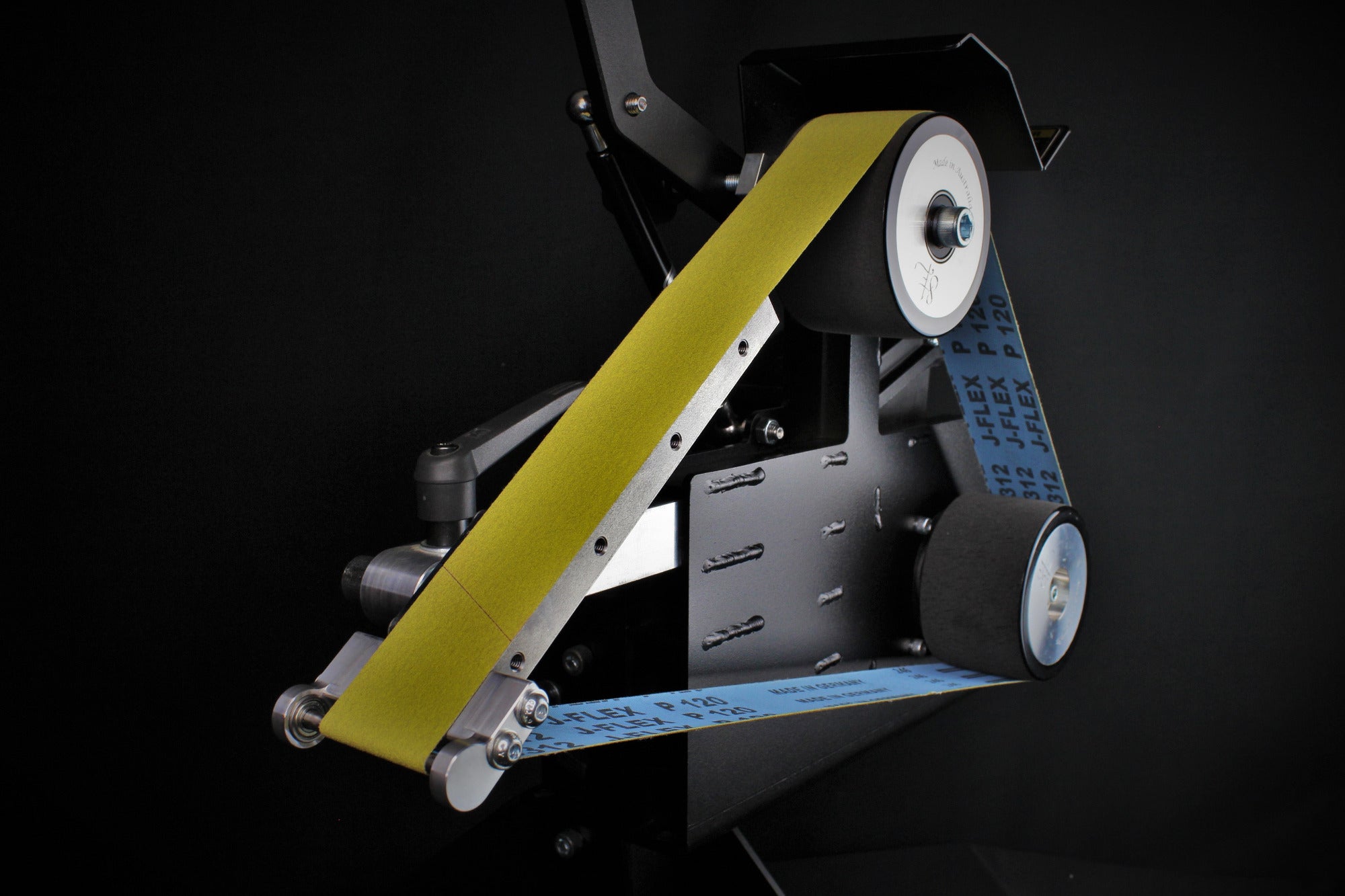

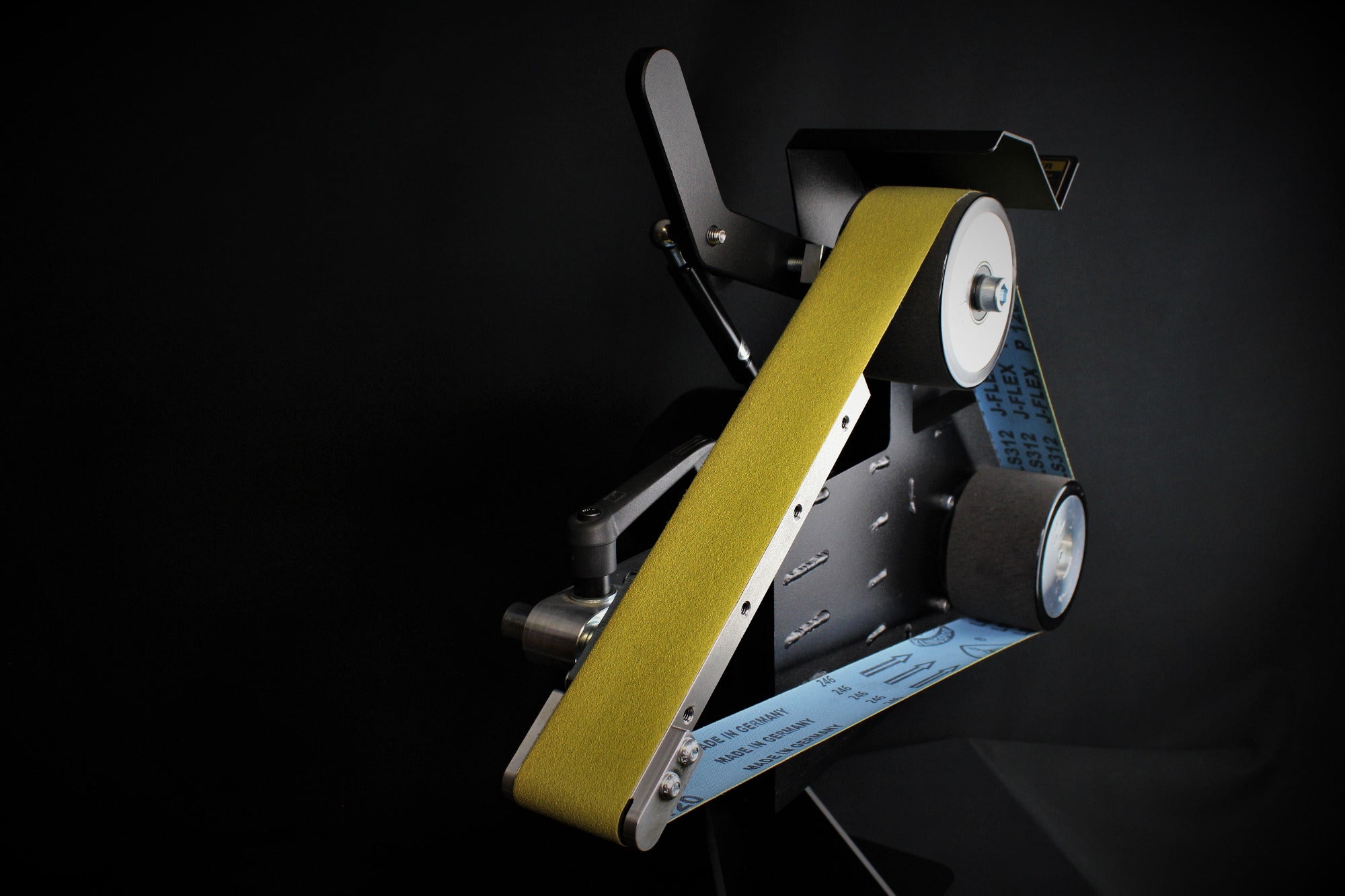

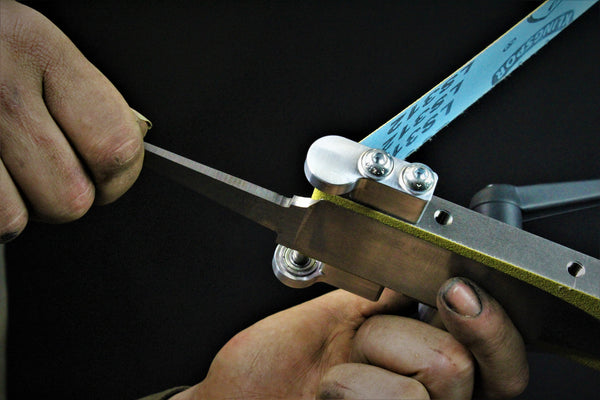

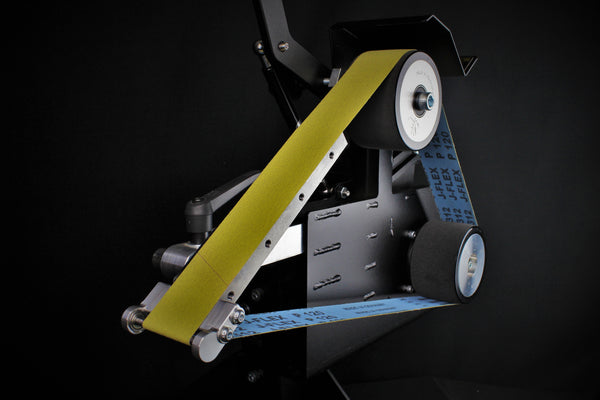

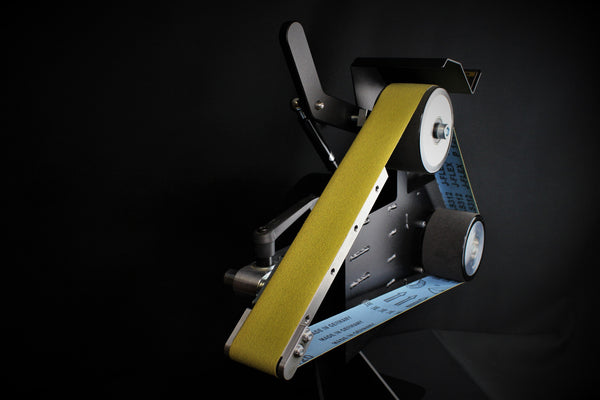

The 84 engineering 6mm, 13mm, 19mm, 25mm and now 50mm plunge platens (sometimes referred to as 'waterfall platen') make the otherwise intricate task of grinding plunge lines and rounded corners simple and repeatable.

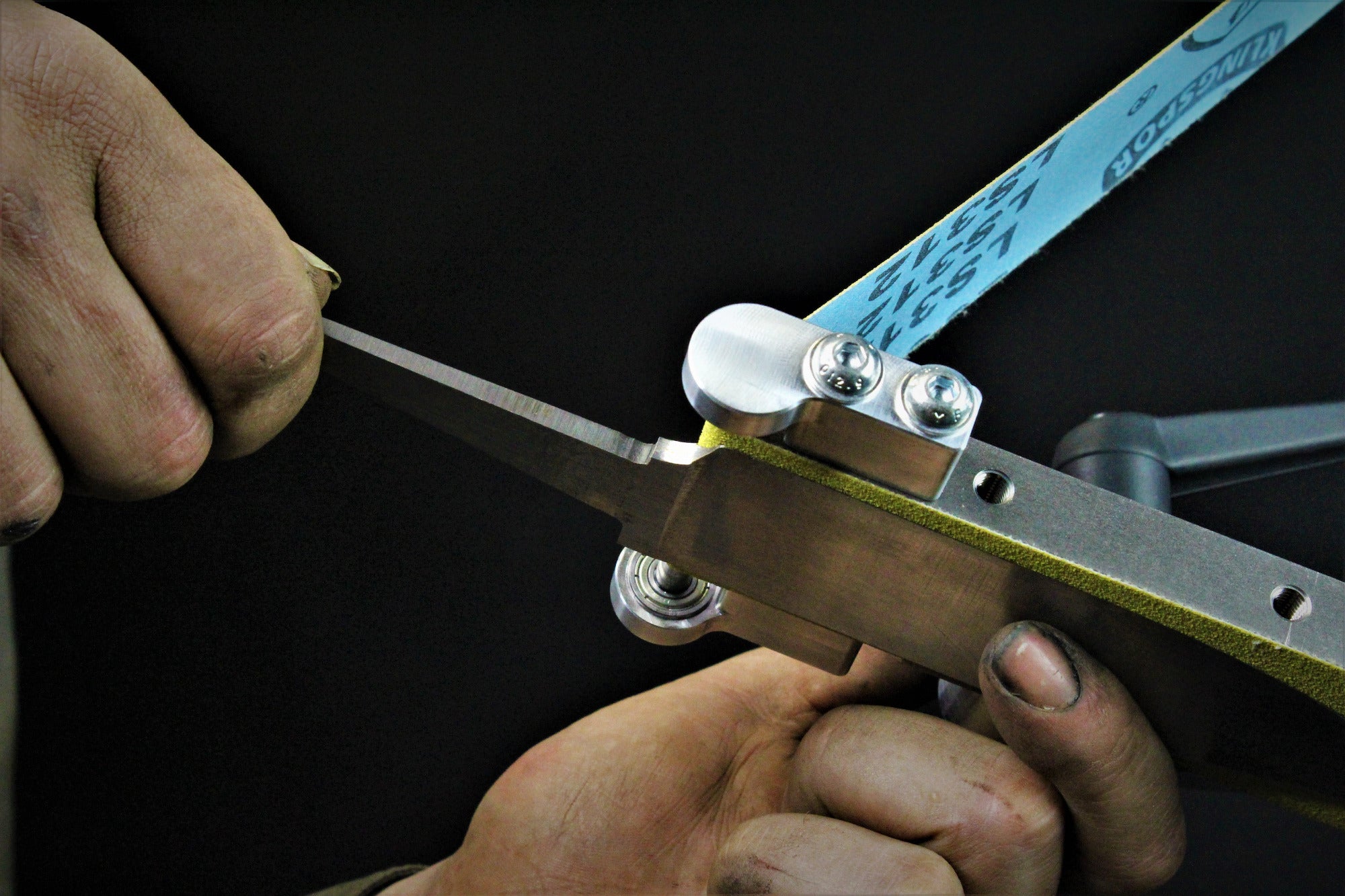

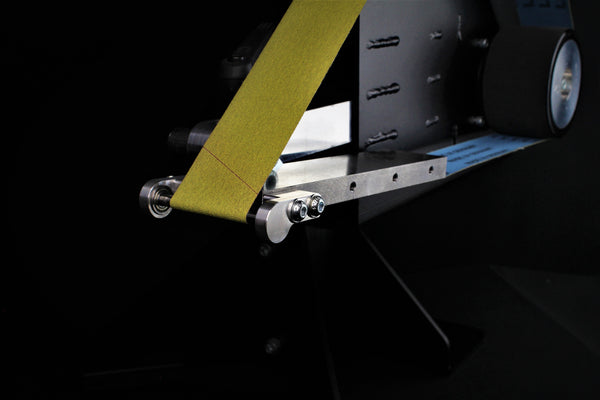

Our plunge platens use a wheel rather than a radiused edge for reduced friction. This equates to cooler grinding and increased belt life.

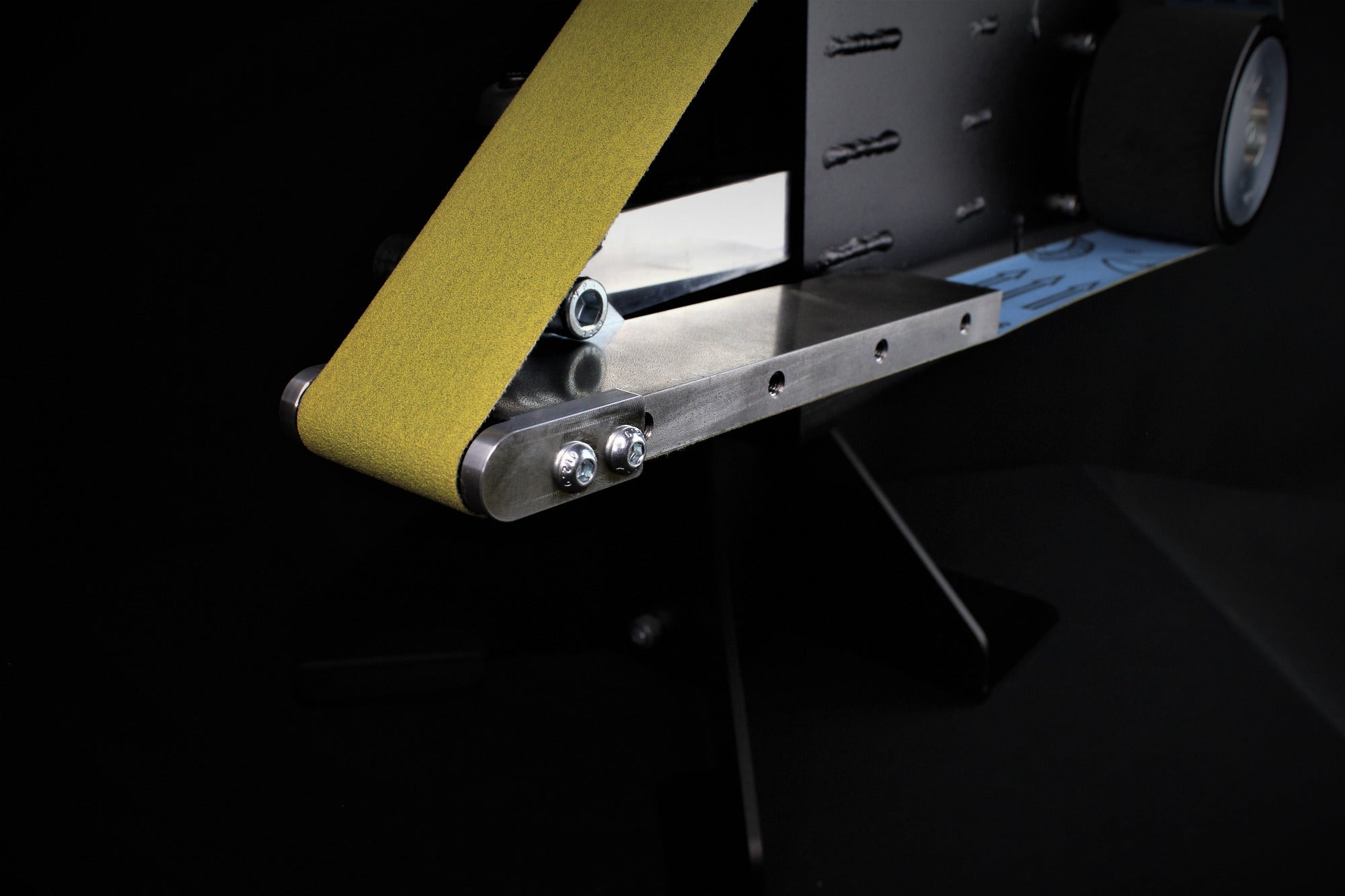

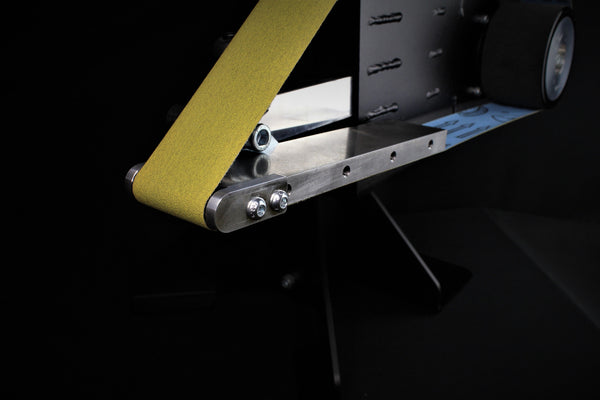

Designed to provide the best finish on your knife, there is minimal gap between the roller and the radiused edge of the platen. The result of this is that the 84 Engineering plunge platen will leave no transition between the wheel and 215mm flat platen, keeping hand sanding to a minimum if required at all.

We recommend the 6mm and 13mm plunge platen for thinner blades and the 19mm and 25mm for integral bolster style blades. The 50mm will give a very subtle transition from your bevel to your ricasso. Our plunge platens use our standard 19mm spigot, so will easily swap out with the included platen on either the Shop Mate 2x48” or Shop Master 2x72” belt grinders / linishers using the standard tooling arms.

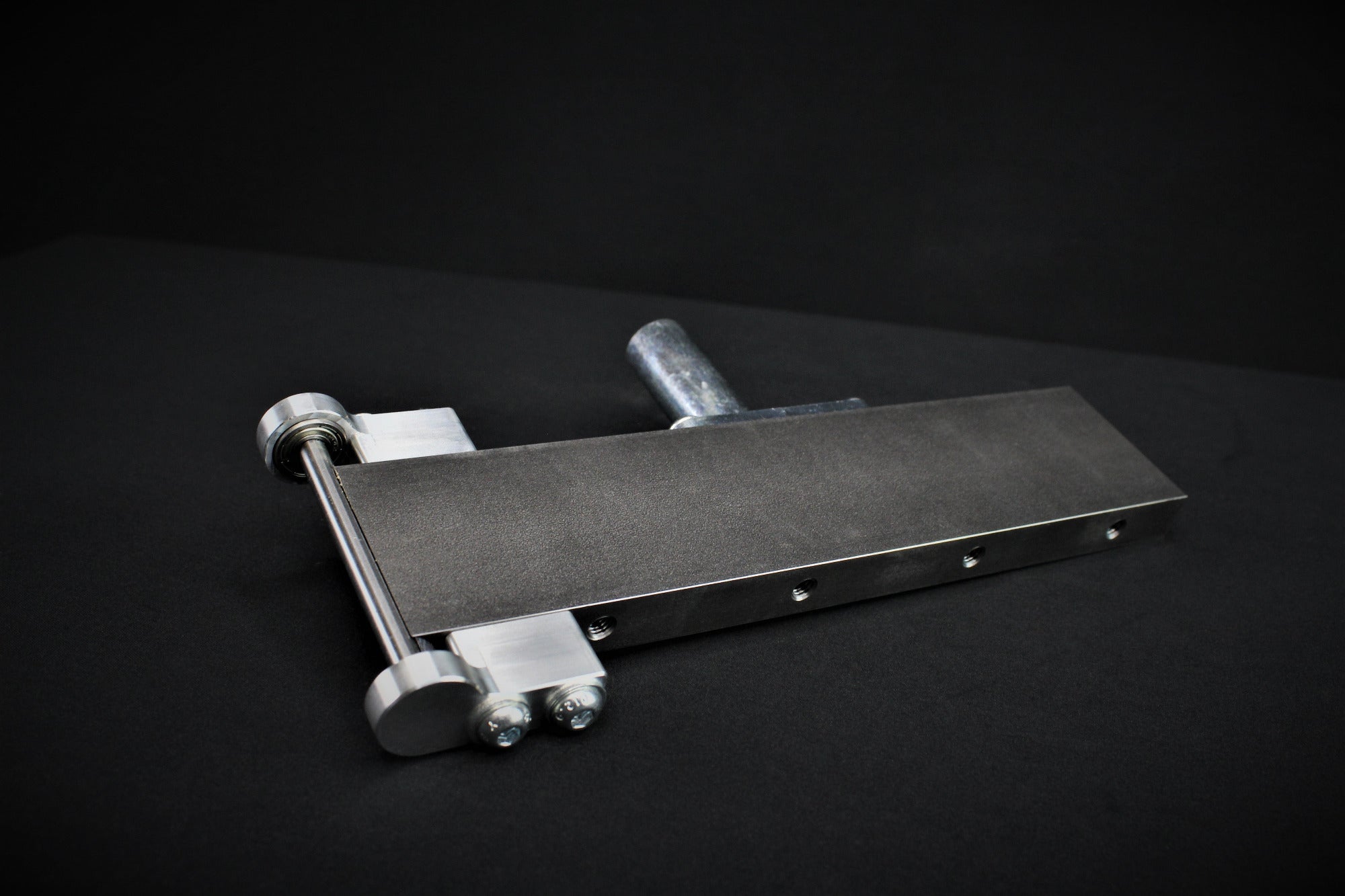

You can also use the plunge platen with a 84 Engineering small wheel arm, resting the back of the platen on the 2" idler wheel. Threaded holes on either side of the plunge platen allow for the spigot to be mounted to either side. This means the plunge platen can be used with the platen facing up or down depending on application or preference.

We recommend the use of light backed belts with these small wheels as heavy Y and Z weight belts do not easily bend to such a tight radius.

Our 3M Cubitron 726A belts are a perfect match for our Plunge Platens.

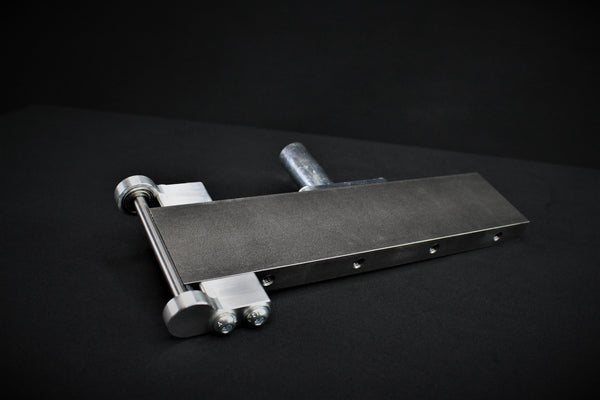

- 215mm steel platen

-19mm spigot

-Spigot can be used platen facing up or down and to suit all 84 Engineering belt grinders

-6mm wheel is made from centerless-ground silver steel

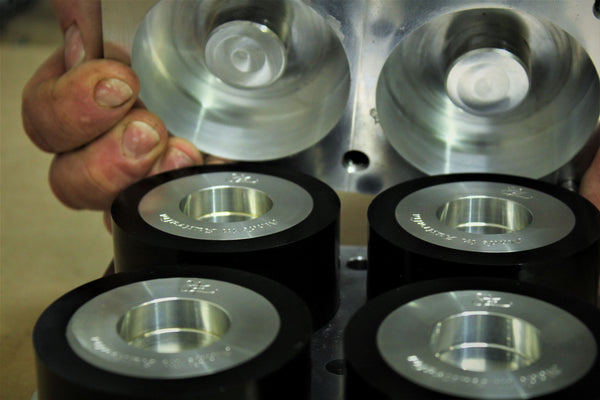

-19mm wheel comprises steel billet center coated in 73 Shore A urethane rubber

-Precision CNC machined aluminium billet brackets

-Plunge platen with selected wheel size

-19mm Spigot & stop collar

Our on-line store is open 24/7 and we ship Monday through Friday, excluding some holidays. Orders received for products without shipping restrictions on its product page will ship the following business day when received before 12:00 p.m. AEST. Orders in high demand will have an estimated production time listed on its product page and will ship according to the date listed.

I chose to wait till I had a bit more experience with the plunge platen as I had previously been doing all my work freehand on a small linisher. The 72 inch grinder with its options has revolutionized how I work and this platen is brilliant. Thanks to the guys at 84 engineering.

John

Arrived quickly . Well made . Wish you could run them faster .

Really a great accessory to my shop. It makes great plunge lines a lot easier and cuts down almost all hand work. The order was seamless to the US. I definitely recommend their work. Well Done.

Freaking amazing thank you

84 engineering’s plunge platen is top quality and the staff were very friendly and helpful. I highly recommend.

Hubs used in our small wheels are CNC machined from steel billet to ensure extreme rigidity and precision

The contact wheel on our 19mm Plunge platen is coated with 73 shore A polyurethane rubber to provide extreme wear & heat resistance. Wheels are then ground perfectly flat to remove any surface variationvariation

84 Engineering use Australian-sourced steel for our grinder components

DP Custom Knives

Have been a long time customer of 84 Engineering and every product I have purchased has been manufactured incredibly well with very high attention to detail. Customer service has also always been top notch. You will definitely be well looked after here.

Deathrig Fabrication

Amazing Aussie made products - used daily in my workshop. Quality second to none

Cafe Racer Garage

I have been using 84 Engineering belt grinders for many years, it's truly the one tool that gets the most use in my garage building motorcycles, It's one of those tools that you wonder how you ever did without! I highly recommend anyone working with steel have one! Dan - Cafe Race Garage -YouTube

Knife Maker

Our 84 Engineering machine is the best in our workshop and the best we've ever owned. Their service is second to none.

Follow us on social media for the latest news, deals and updates

© 2026, 84 Engineering Powered by Shopify