Current lead time on grinder orders is 3-4 days

Due to the weight and size of the Gibson 72" belt grinder (115kg), shipping options can be tricky! Included in the price is free delivery Australia-wide, however in order to arrange the correct transport, we need you to specify the following:

- If you have a forklift to unload, great! Just order as normal.

- If you are in an area serviced by TNT and have good truck access, but don't have a forklift, please specify 'TAILGATE DELIVERY REQUIRED' in the 'ORDER SPECIAL INSTRUCTIONS' section.

- If you are in a remote area or your address has a steep driveway / poor truck access, please specify 'COLLECT FROM TNT DEPOT' in the 'ORDER SPECIAL INSTRUCTIONS' section. TNT will phone you once goods have arrived in your nearest depot and assist with loading your vehicle.

If you need help, please don't hesitate to contact us on 0448 531 822 or email us at team@84engineering.com.au

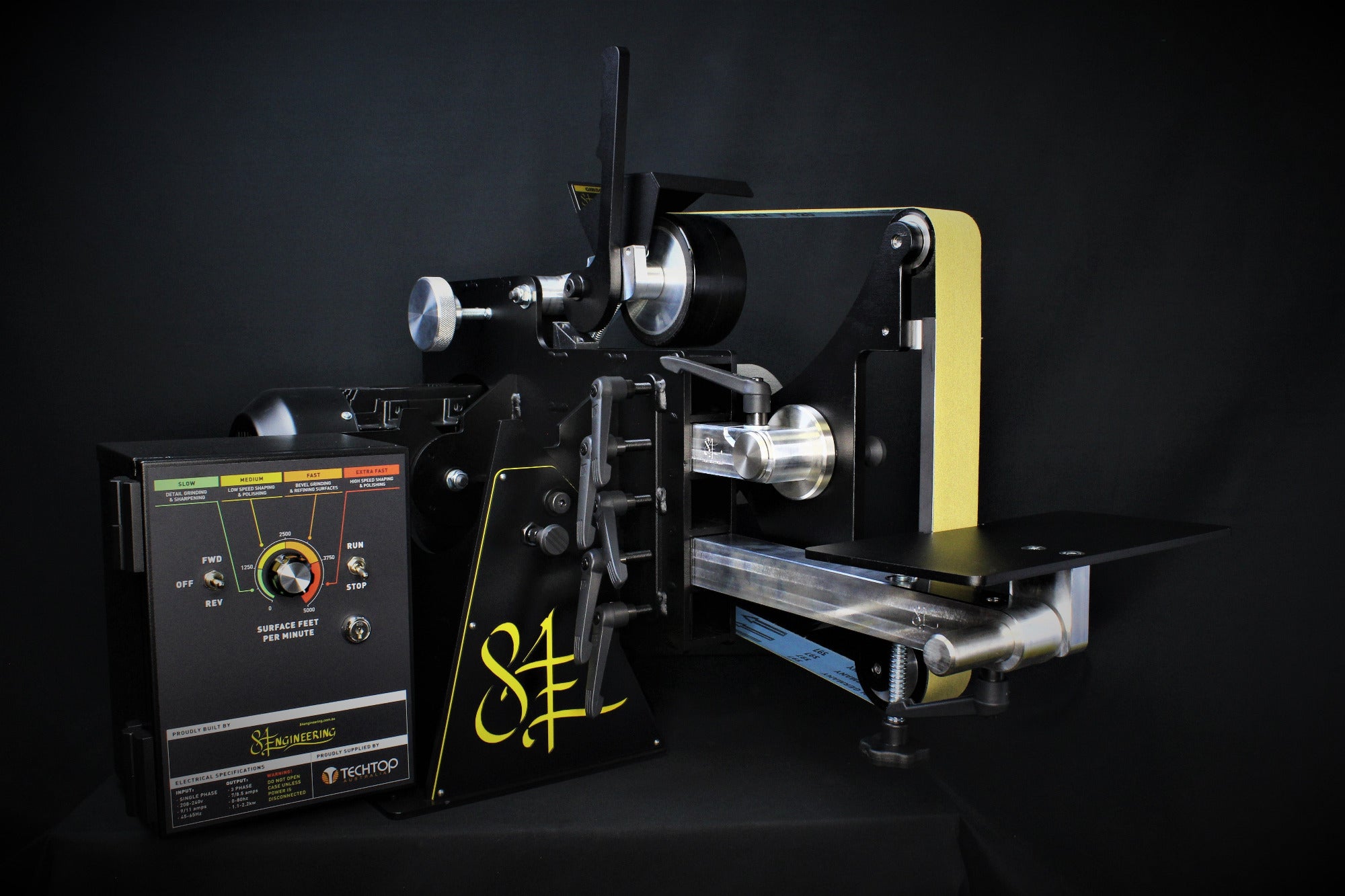

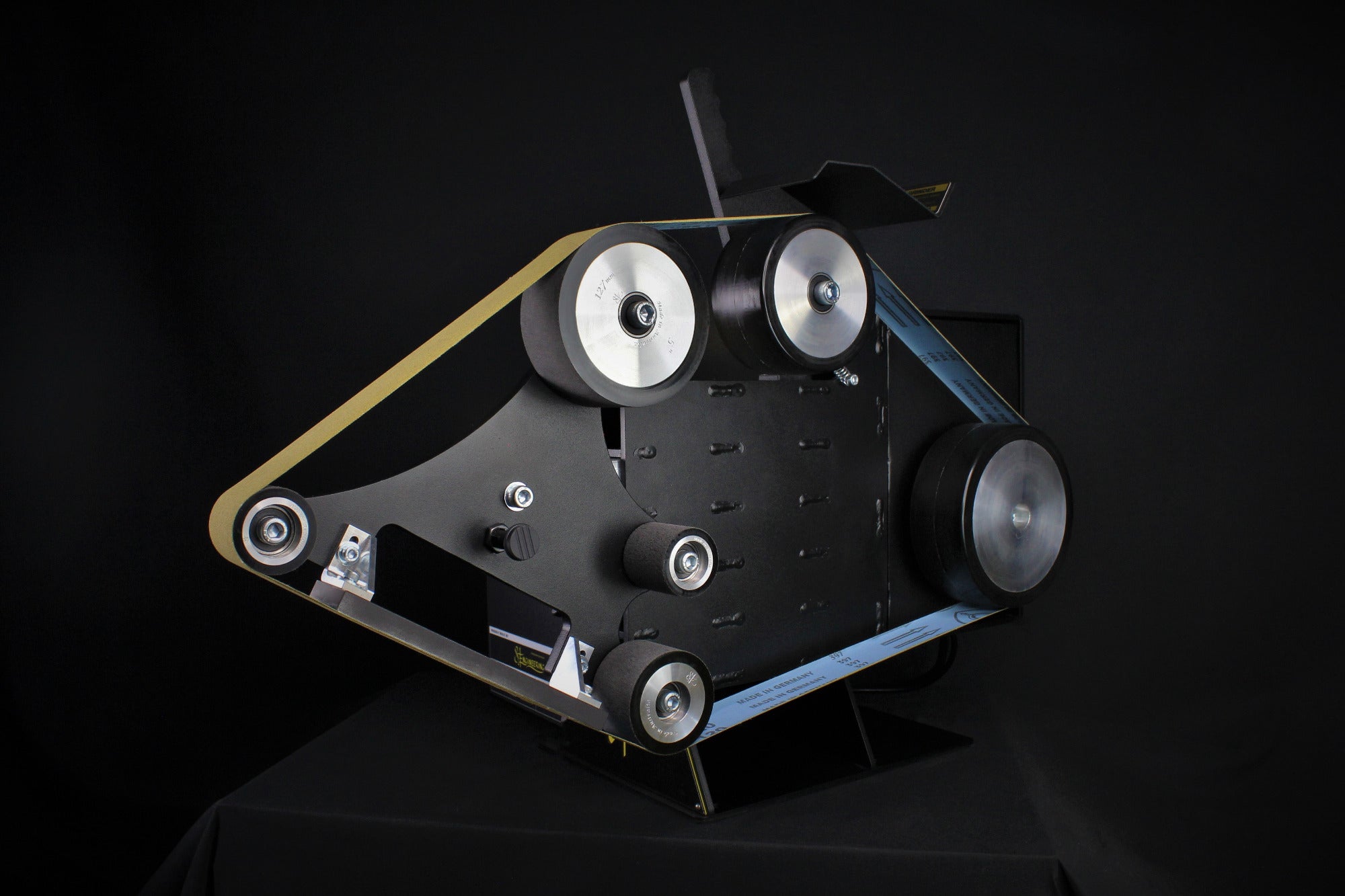

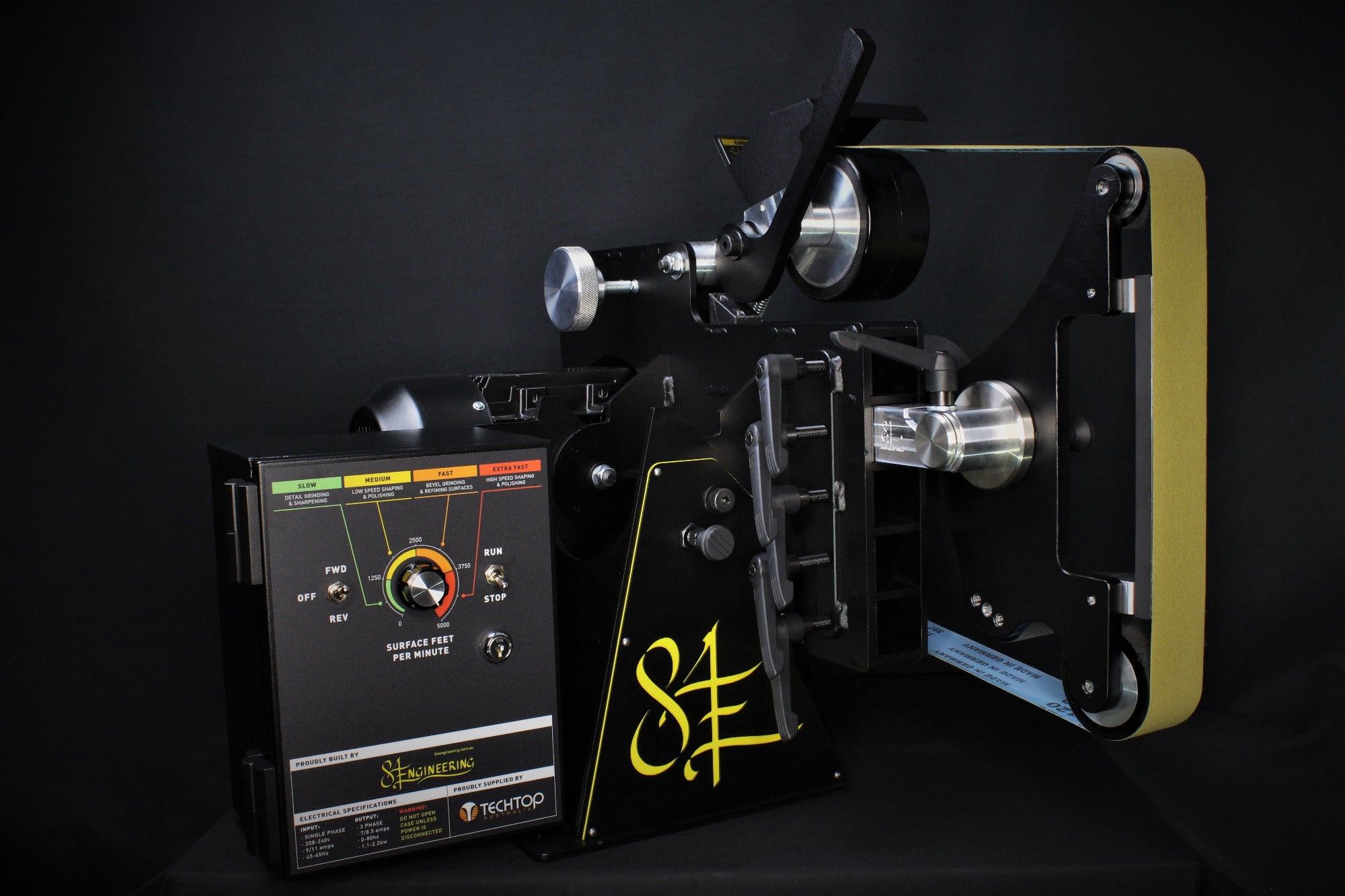

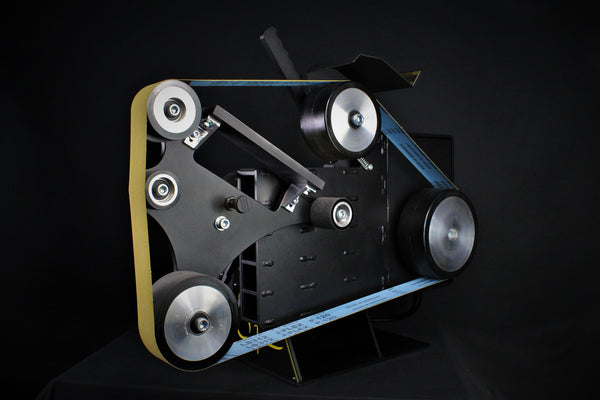

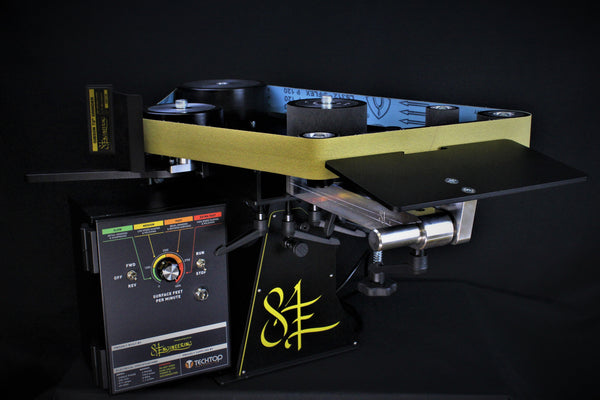

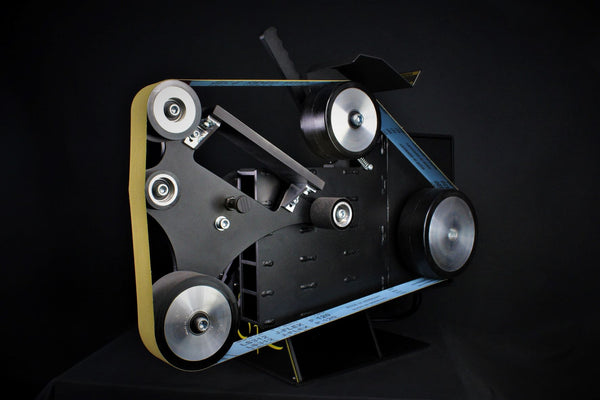

This is our latest masterpiece offered up to satisfy the professional needs of artisan black smiths / knife makers and industrial steel workers alike. The impressive list of features is complimented by its rigid construction, guaranteed to satisfy the demands of heavy-duty grinding projects.

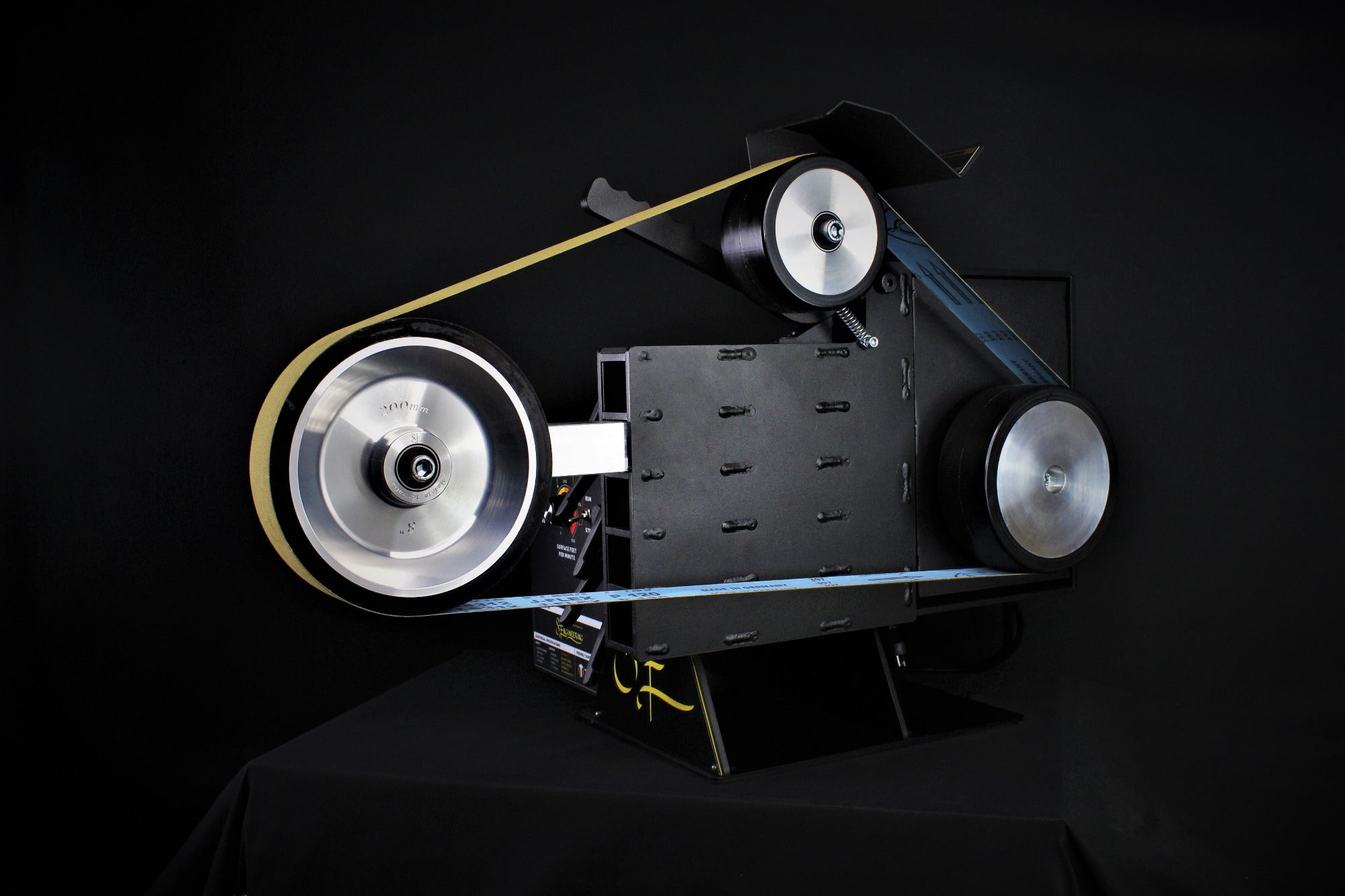

The Gibson 72" grinder body and stand start life as 6mm Australian-made sheet steel. The components are precision laser cut before being assembled with more than 35 high-strength seam welds. Weighing in at over 85kg, the Gibson 72 is one of the most rigid and stable platforms on the belt grinder / linisher market. This mass and rigid construction not only ensures accuracy and perfect alignment in all grinding / linishing scenarios, but makes for a smooth & vibration-free experience.

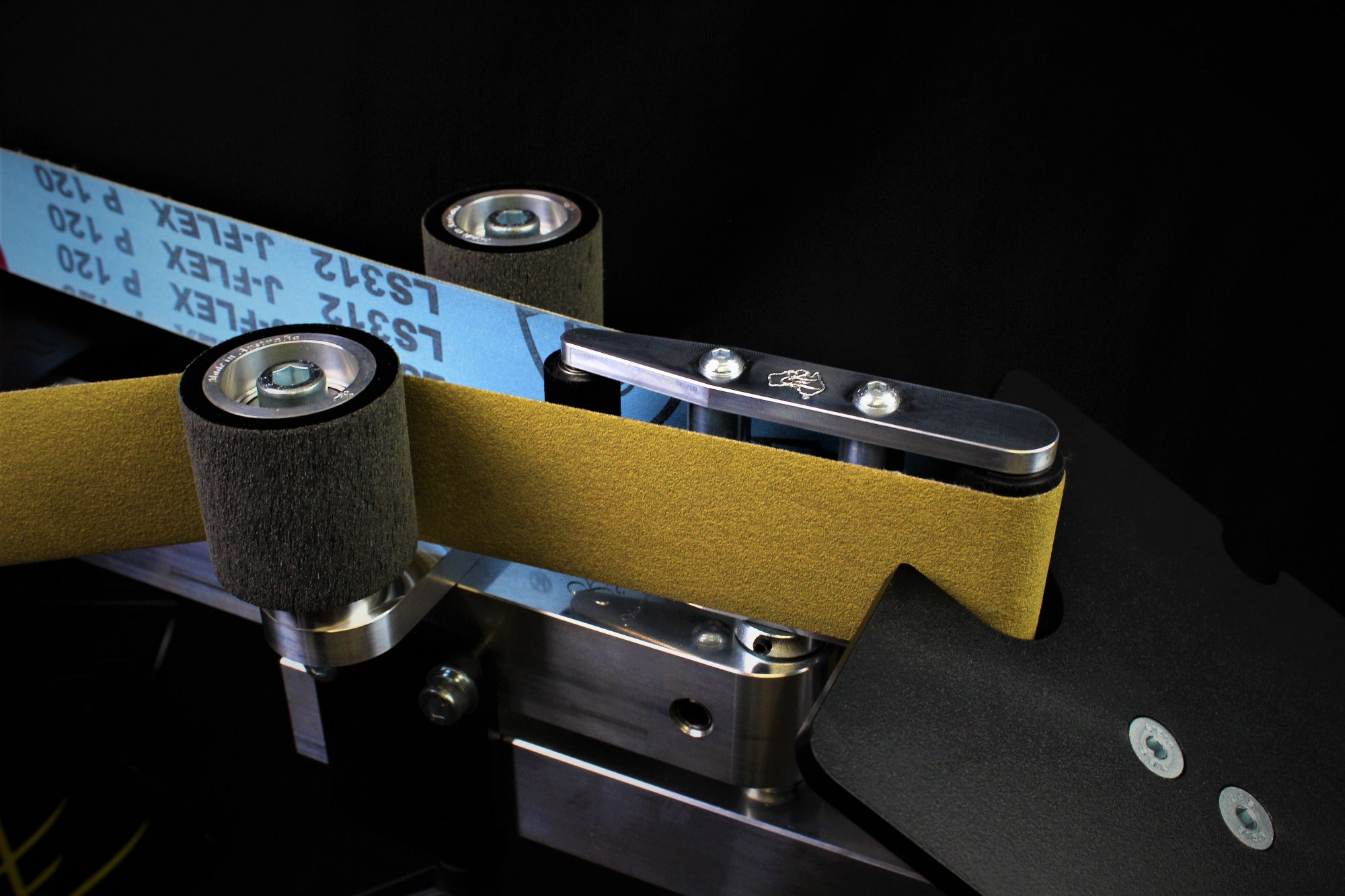

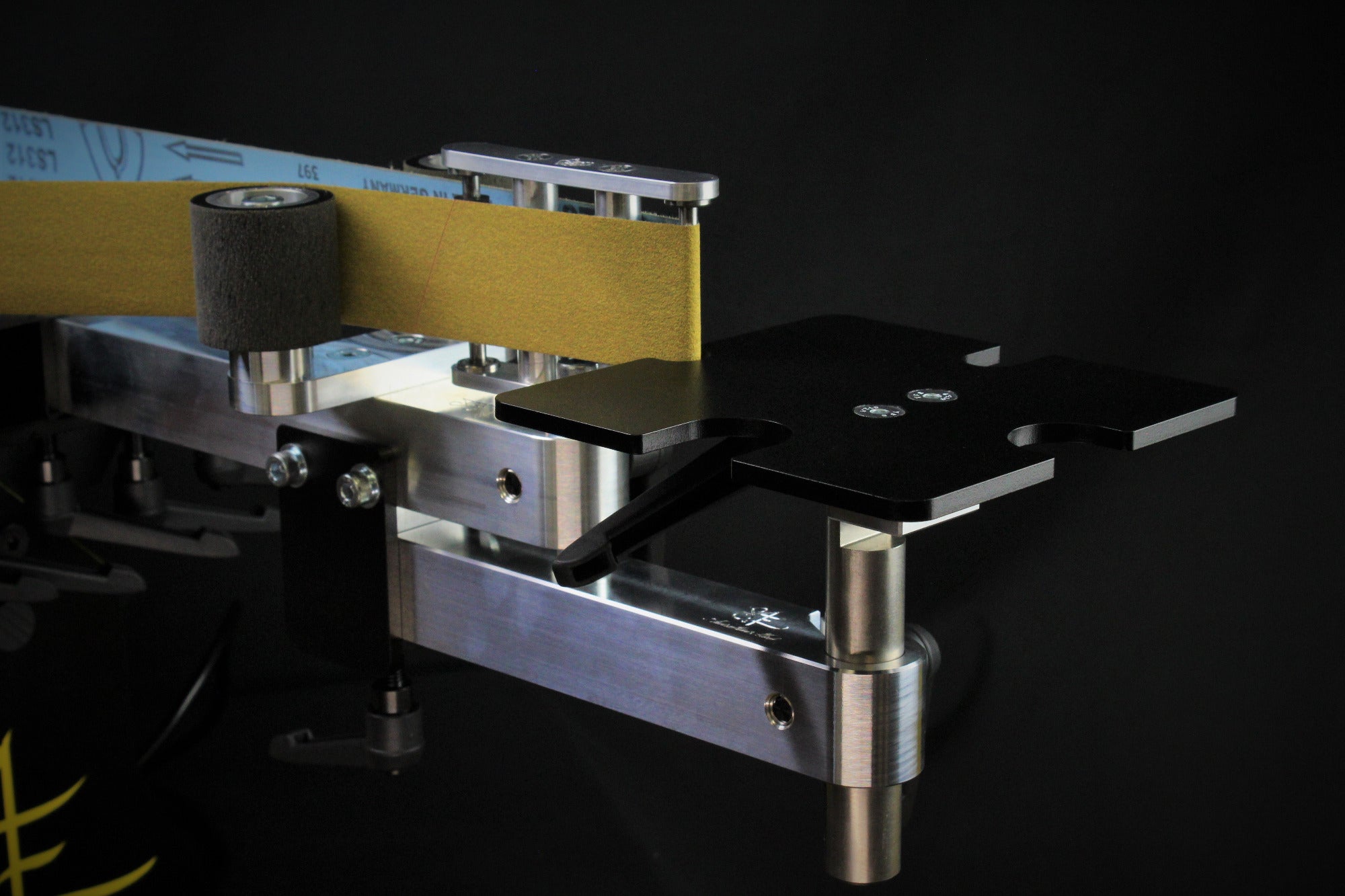

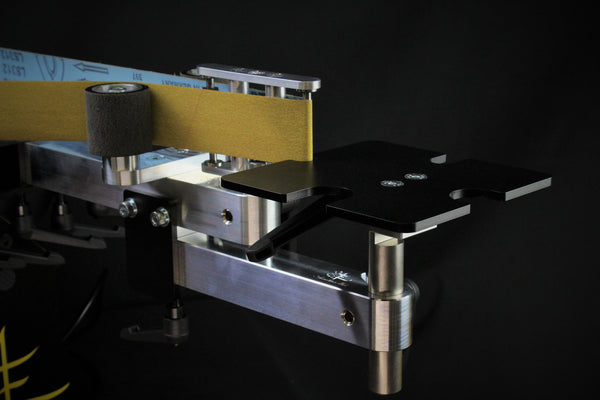

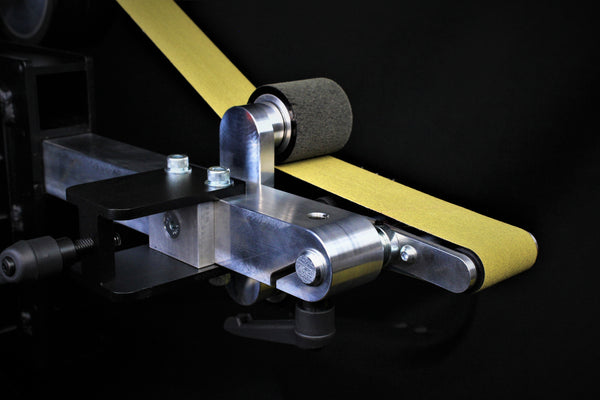

The auxiliary components and attachments on the Gibson 72 maintain this over-engineered philosophy and premium build quality. The 40x40mm tooling arms, single-piece tension mechanism and over-sized tracking knob and are CNC machined from 6061 aluminium billet. The ergonomic tension handle and rotating platen-support are laser cut from 12mm plate steel, and over-sized 25mmØ tooling spigots and the platen rotating/indexing mechanism are turned from stainless steel bar, making for a bullet-proof platform that will look great even after years of punishment.

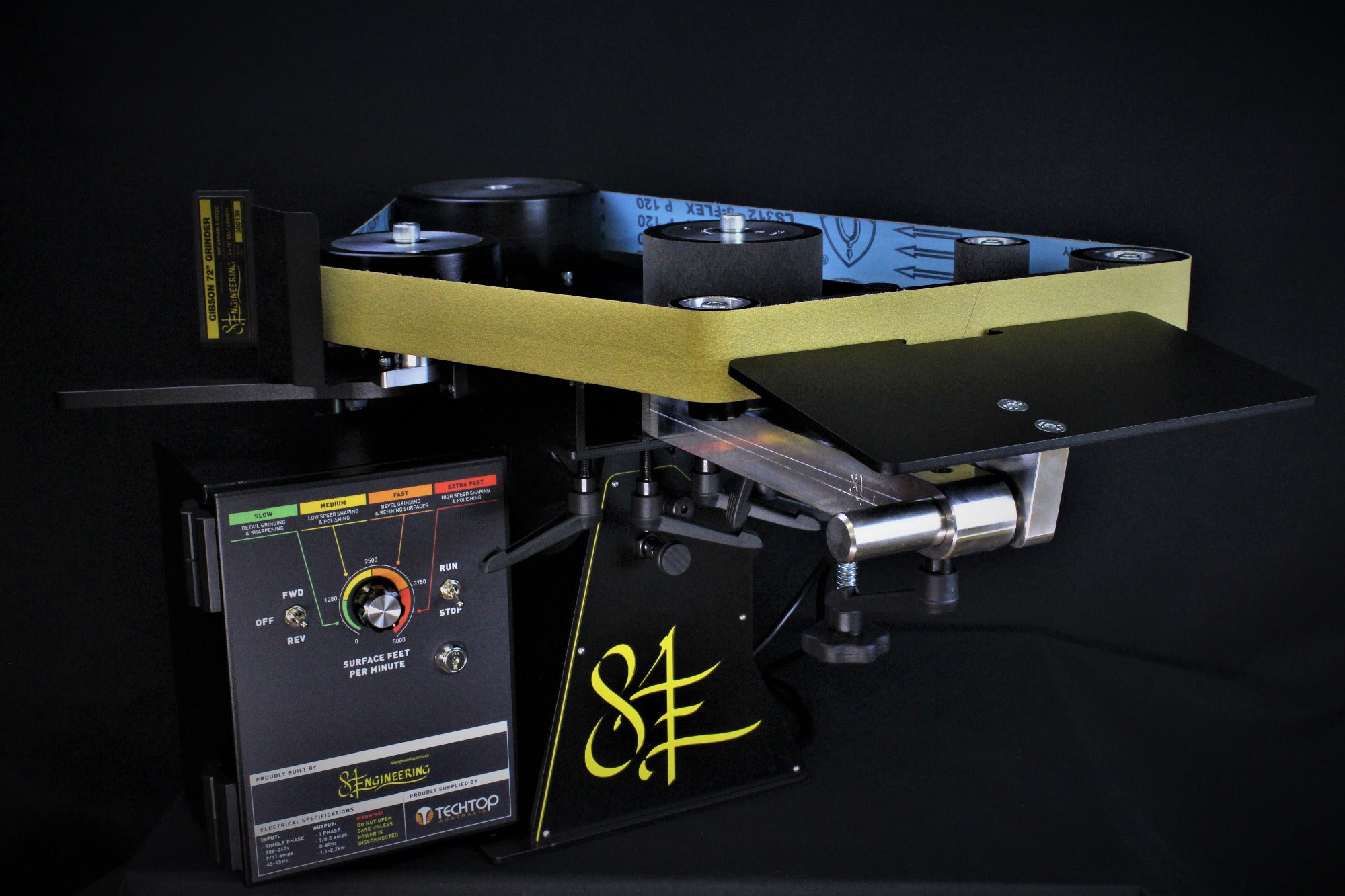

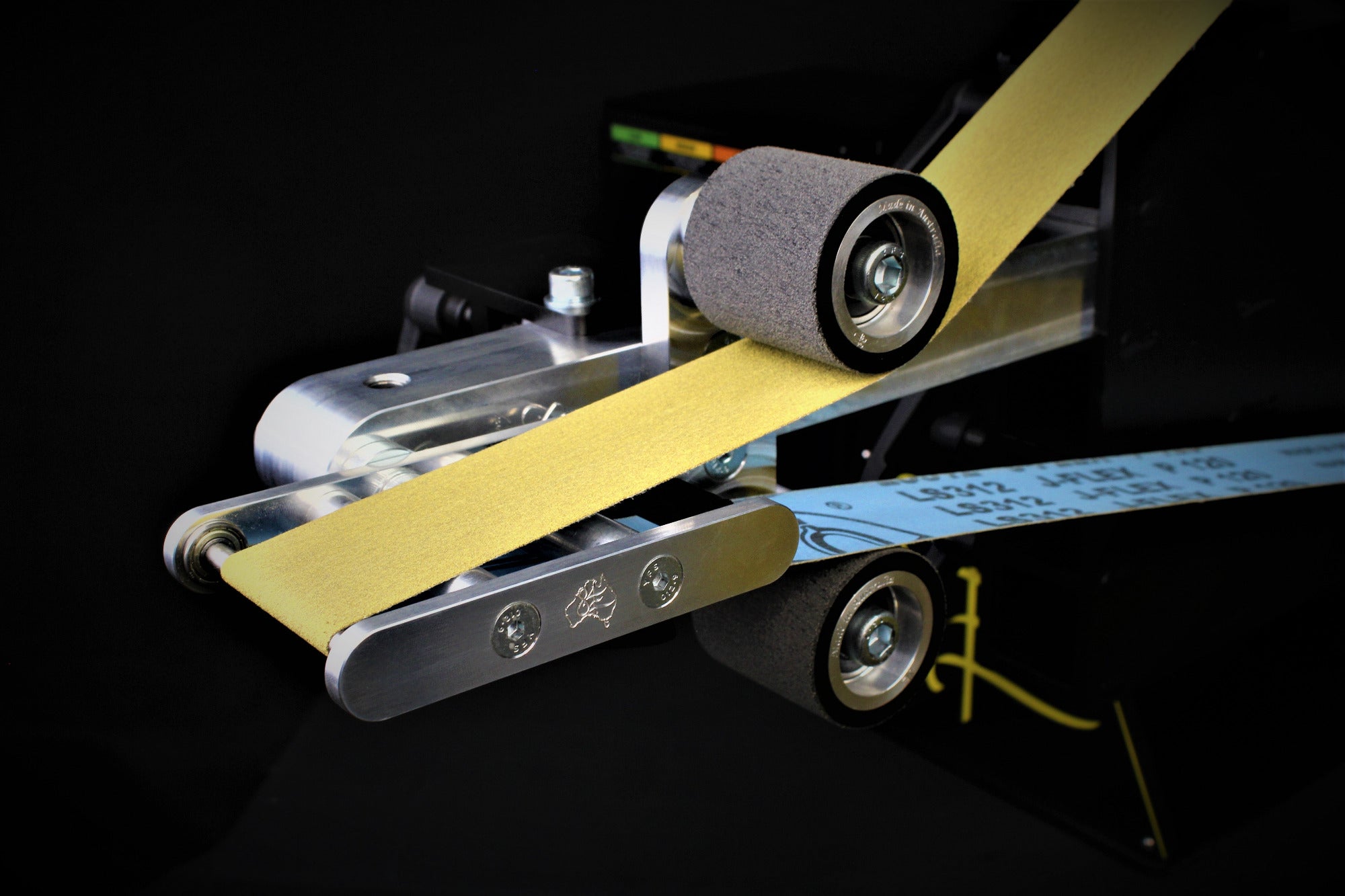

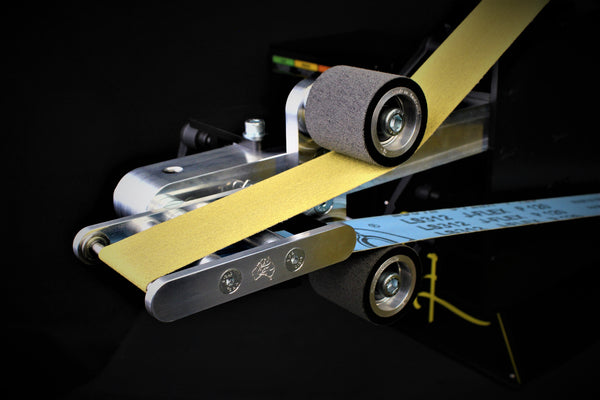

Included with every Gibson is a small wheel rest, 300x150mm chamfered angle-adjustable work rest, small wheel idler arm, ¼”, ½”, ¾” & 1” (6mm, 13mm, 19mm & 25mm) small wheel sets, and an extremely versatile rotating platen.

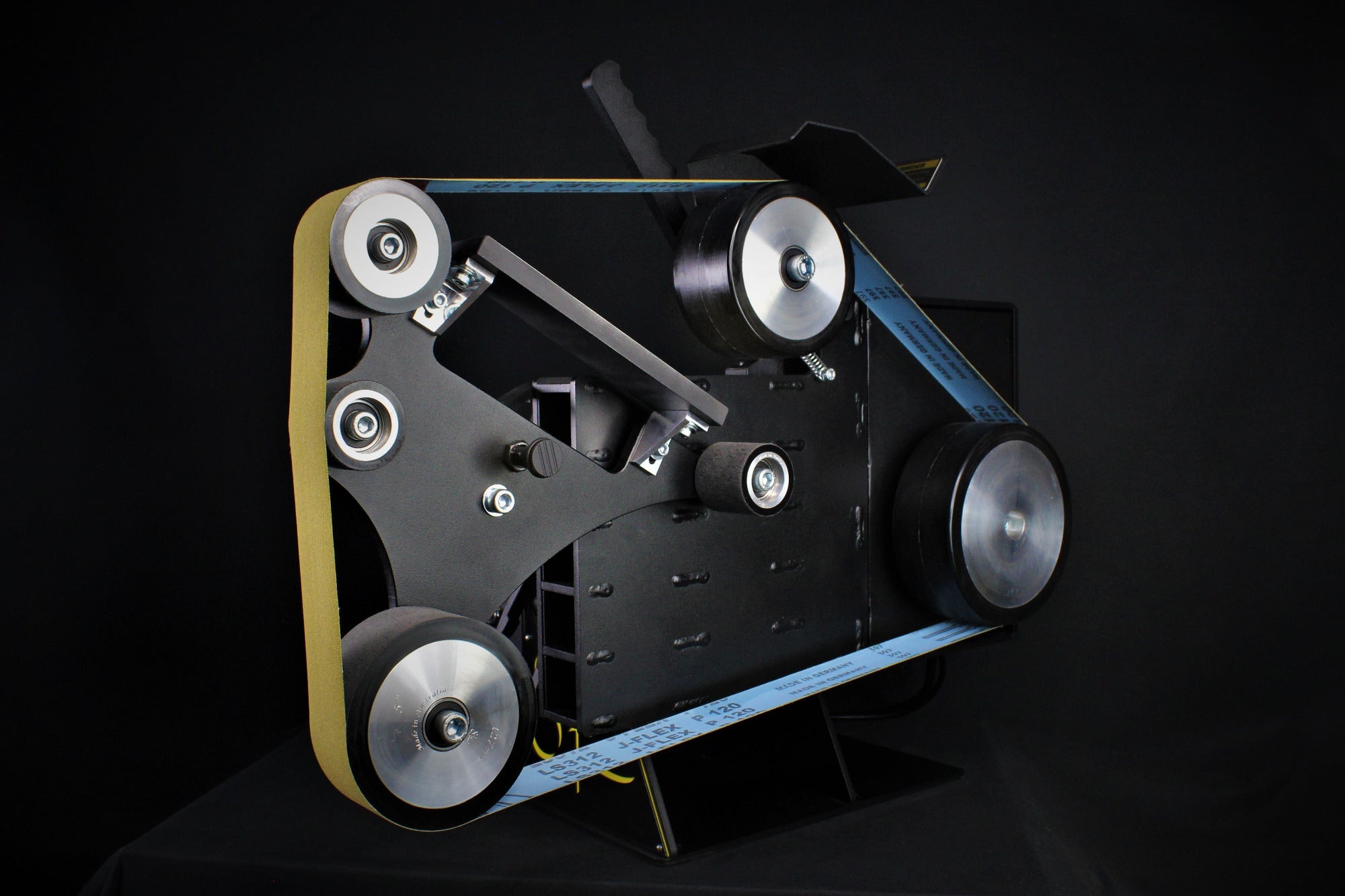

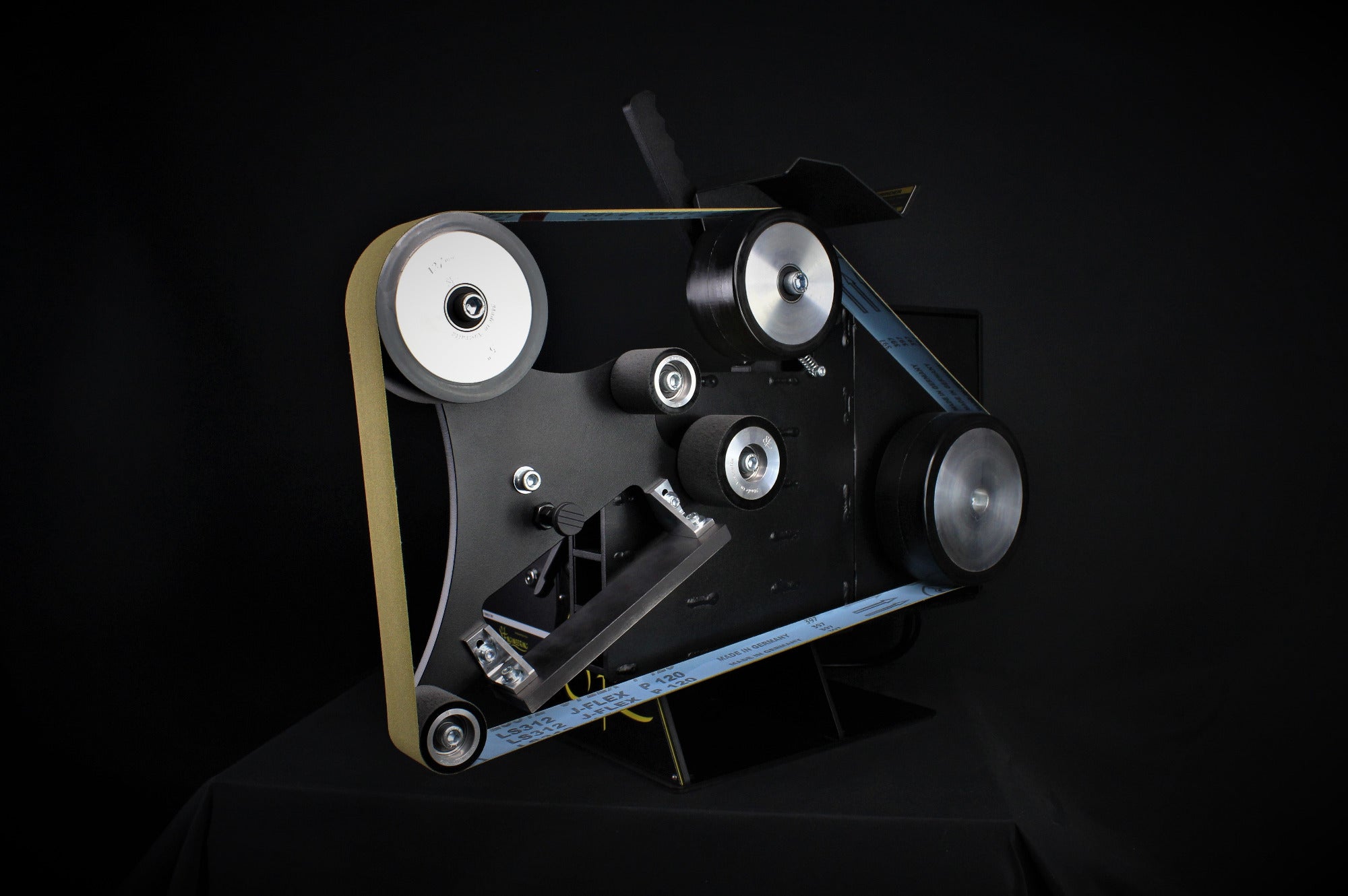

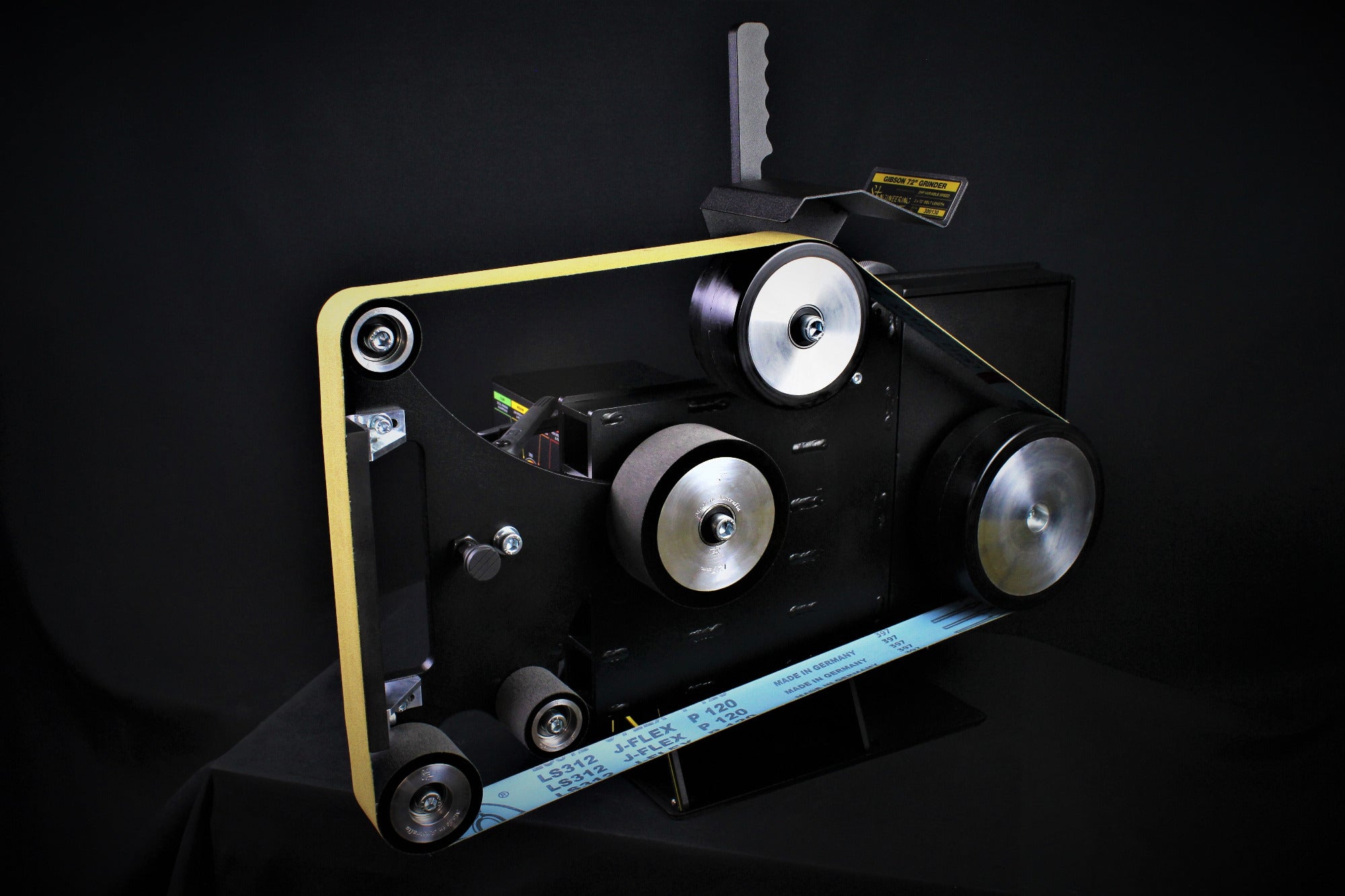

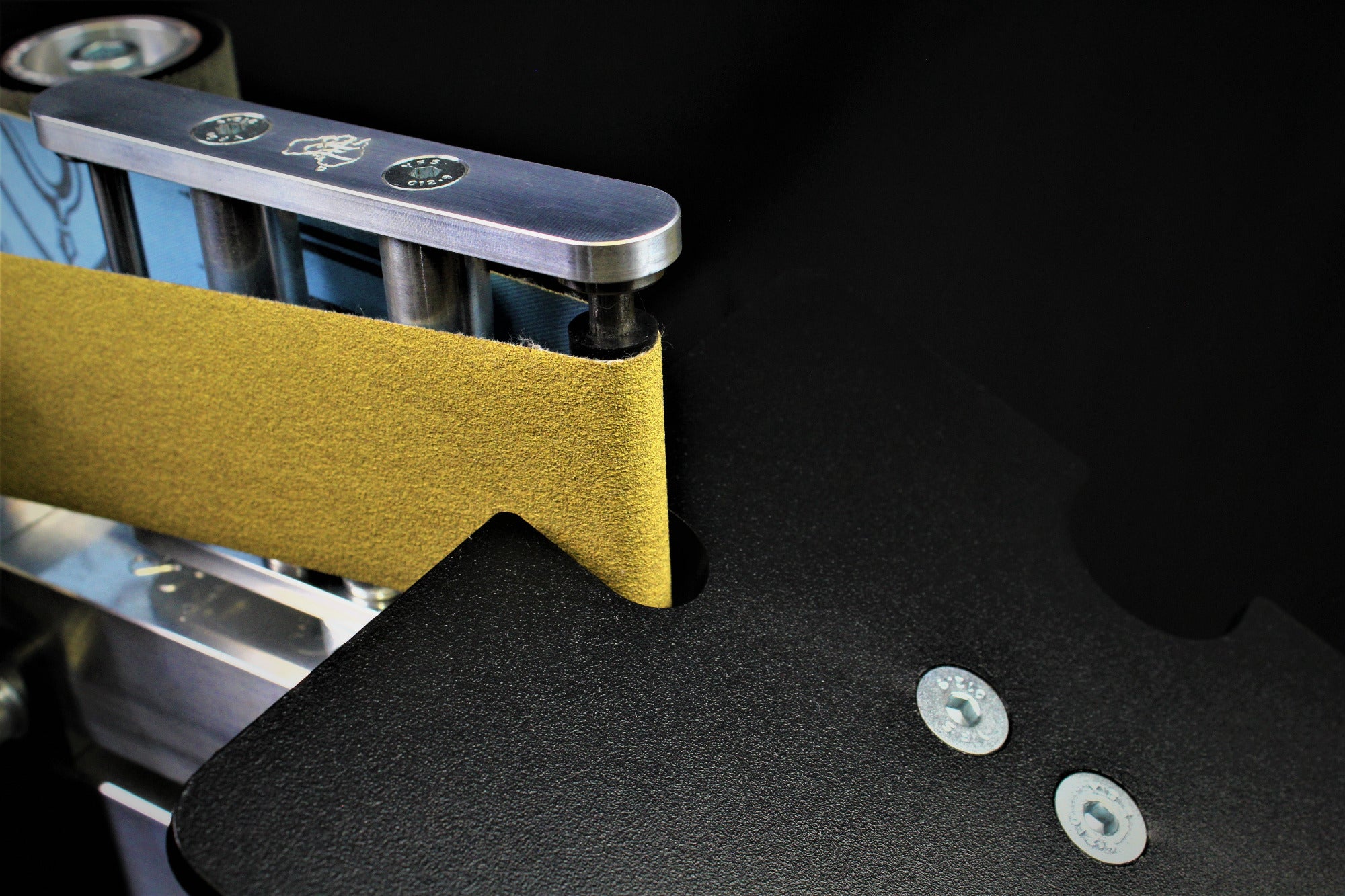

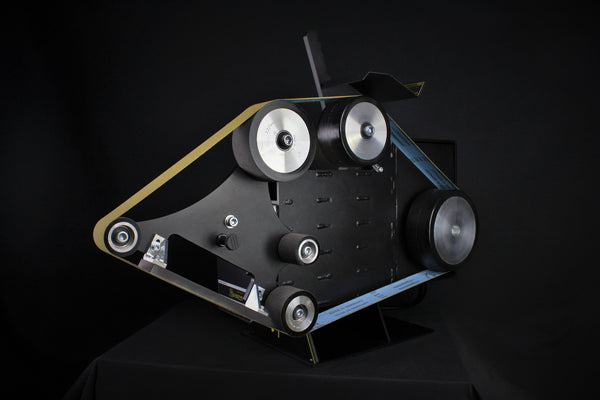

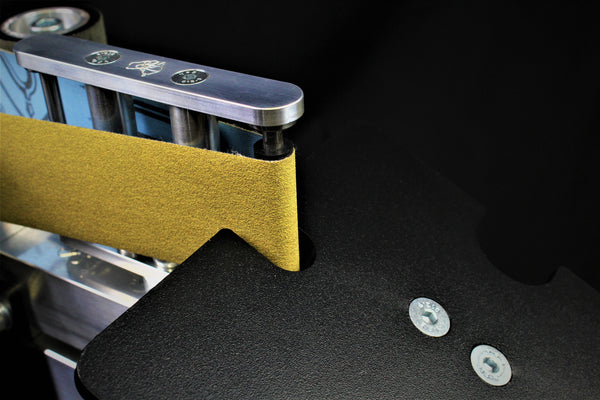

Simply loosen the locking handle and rotate the entire platen assembly to access 7 separate grinding setups! Utilise 2 x 2”, a 3” and a 5” contact wheel, a hardened 215mm D2 flat platen and 3 different slack belt lengths without removing a tooling arm! For consistency and ease of setup, the platen assembly also includes a spring-loaded indexing pin that has 12 locking positions at 30-degree intervals.

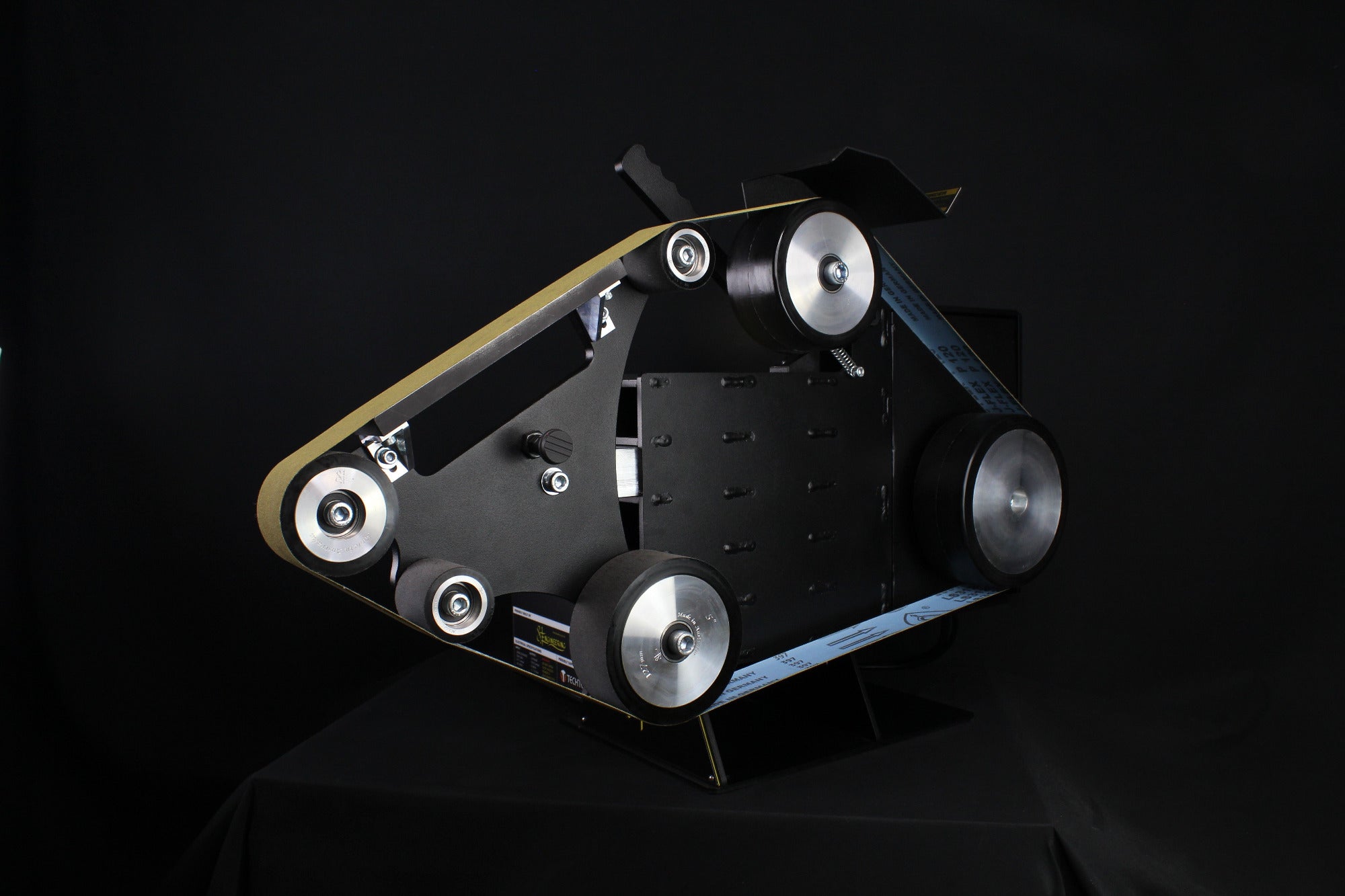

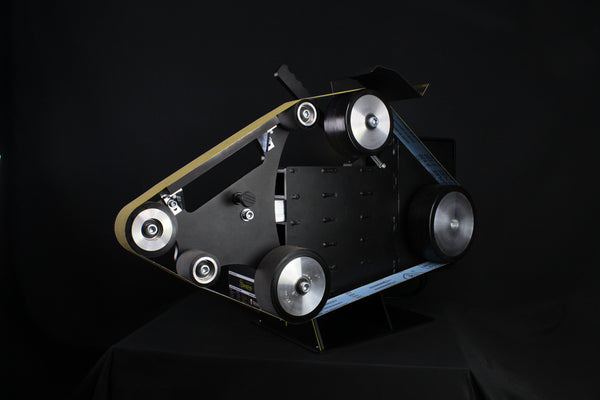

Platen support design on the Gibson 72 also allows for excellent access on either side of the flat platen or contact wheels for un-interrupted grinding of edges, reliefs and awkward work pieces. The in-built tilting stand allows the grinder to be used in both vertical and horizontal orientations, opening a plethora of grinding configurations and unlocking the potential of attachments like the Small Wheel Pairs.

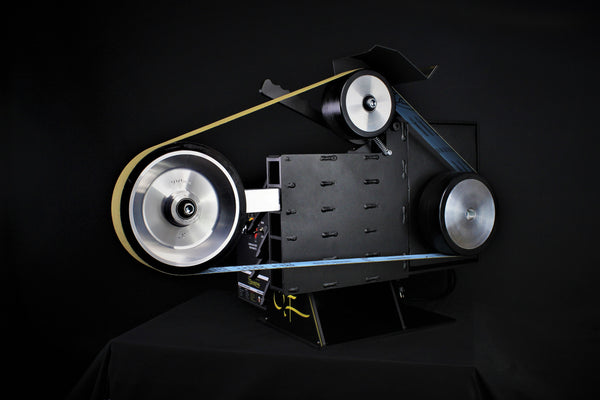

The Gibson 72” belt grinder will plug into any standard 240v 10a power socket. The included Variable Frequency Drive (VFD) is encased in a custom water/dust resistant enclosure and converts power to a 3-phase signal, driving the 2.2kw (3hp) 4-pole motor. This powerhouse of a setup spins a 7” drive wheel coated with high-traction 65 Shore A urethane rubber to generate a maximum belt speed of 5000 surface feet per minute. You can hog material at an epic rate or run the belt slowly enough for fine shaping, sharpening and polishing – the infinitely variable speed controller providing maximum torque throughout the 0-5000SFM speed range.

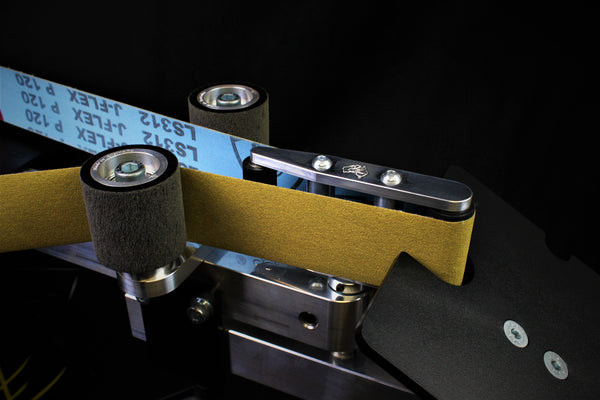

All contact wheels on the Gibson 72” linisher are precision CNC machined from 6061 billet aluminum and coated in our newly formulated abrasion-resistant urethane rubber. Rubberised wheels make for quieter operation and even out belt discrepancies, meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit belts.

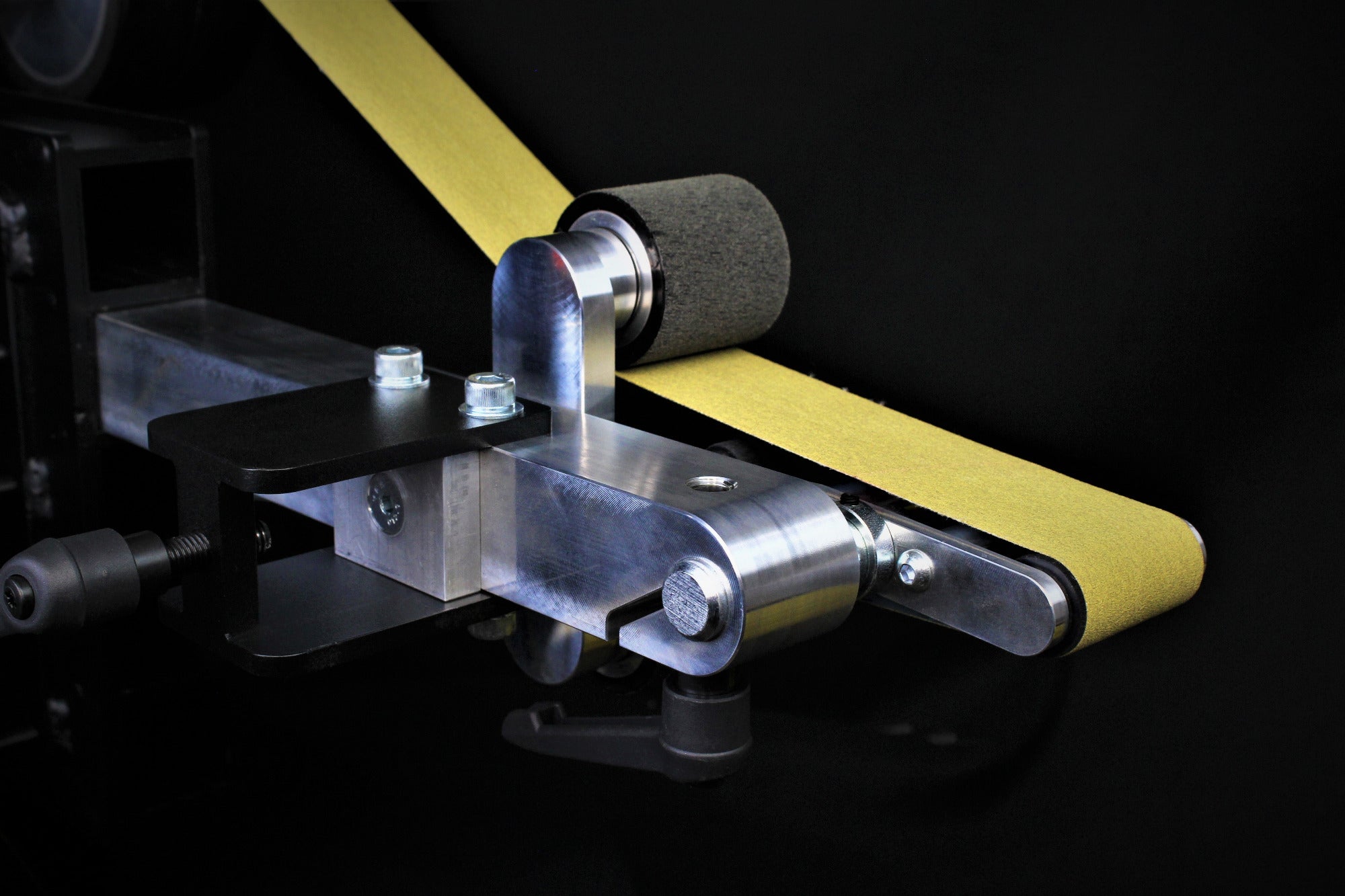

The Gibson belt grinder uses a unique drive-wheel tracking system whereby the whole motor mount tilts to adjust belt alignment. This design offers superior tracking characteristics, maintaining alignment under heavy loads and varying belt tensions.

Another key feature of the Gibson grinder is the adjustable tensioning mechanism. The grinder tensioning mechanism uses a combination of acetyl bushes and a cam mechanism to easily and infinitely adjust your belt tension to suit the job. Simply use the ergonomic tensioning handle to tighten or loosen the belt. This feature comes in especially handy for using slack belts, and makes belt changes a quick, single-handed operation.

As with all 84 Engineering belt grinders / linishers, the Gibson is compatible with our range of accessories including the popular Surface Grinder attachment. The Gibson is fully assembled in a shipping crate and is tested and fine-tuned in our workshop prior to shipping.

-2 × 72” belt length

-2 hp 4 pole motor with 7” drive wheel for excellent belt speed and torque

-Techtop variable frequency drive in sealed 84 Engineering enclosure

-0 – 5000 surface feet per minute belt speed

-8.5” Hardened D2 faced flat platen

-Indexable 7 way rotating platen

-Adjustable length slack belt

2”, 3” and 5” contact wheels

-Rubber coated wheels for smooth performance and great belt traction

-Drive wheel tracking for perfect belt alignment

-Fully welded frame

-5 arm slots

-Infinitely adjustable belt tension

-Flips from vertical to horizontal

-Large work rest with micro angle adjustment

-Pressure plates to ensure tooling arms are not damaged

-Protective spark guard

-Benchtop tilting stand

-Made in Australia

-Grinder body with horizontal tilting, 4-pole 2 hp motor, variable speed drive, and 180mm/7” drive wheel

-Rotating platen with hardened D2 flat platen, 50mm/2”, 75mm/3”, and 125mm/5” contact wheels

-Large angle adjustable tool rest

-Twin-idler small wheel tool arm

- 1/4" (6mm), 1/2" (13mm), 3/4" (19mm) & 1" (25mm) small contact wheels

- Small contact wheel tool rest

Our on-line store is open 24/7 and we ship Monday through Friday, excluding some holidays. Orders received for products without shipping restrictions on its product page will ship the following business day when received before 12:00 p.m. AEST. Orders in high demand will have an estimated production time listed on its product page and will ship according to the date listed.

What a great bit of kit great service as well!!!!

Keep up the good work Ewan and crew!!

Hi Ewan, I haven’t been able to use the new grinder much as yet as I’m reconfiguring my workshop. I plan to pedestal mount it as far away from my lathe and mill as possible due to the rapid material removal that it can achieve. Very well built and smooth in operation. Packaging on delivery was excellent .Very happy!

Fantastic machine!

The Gibson is a great product that runs perfectly straight out of the box. Delivery was fast and i would recommend buying one.

Excellently presented machine, hell, even the packaging was top notch!

The thought that has gone into it is impressive as is the quality of the materials used to build it..

Worth every cent - now all I have to do is learn how to drive it ...........

The Gibson 72 rotating platen assembly allows you to easily change between 210mm hardened D2 platen, 2" contact wheel, 3" contact wheel, 5" contact wheel and 3 different slack belt options with the twist of a handle.

The Gibson 72 adjustable belt tension mechanism is great for slack belts and makes belt changes a breeze - you can even manage it single handed!

The unique drive wheel tracking mechanism on the Gibson 72 provides extremely stable tracking under all belt load and tension scenarios

DP Custom Knives

Have been a long time customer of 84 Engineering and every product I have purchased has been manufactured incredibly well with very high attention to detail. Customer service has also always been top notch. You will definitely be well looked after here.

Deathrig Fabrication

Amazing Aussie made products - used daily in my workshop. Quality second to none

Cafe Racer Garage

I have been using 84 Engineering belt grinders for many years, it's truly the one tool that gets the most use in my garage building motorcycles, It's one of those tools that you wonder how you ever did without! I highly recommend anyone working with steel have one! Dan - Cafe Race Garage -YouTube

Knife Maker

Our 84 Engineering machine is the best in our workshop and the best we've ever owned. Their service is second to none.

Follow us on social media for the latest news, deals and updates

© 2025, 84 Engineering Powered by Shopify