Free Shipping Australia wide on orders over $100

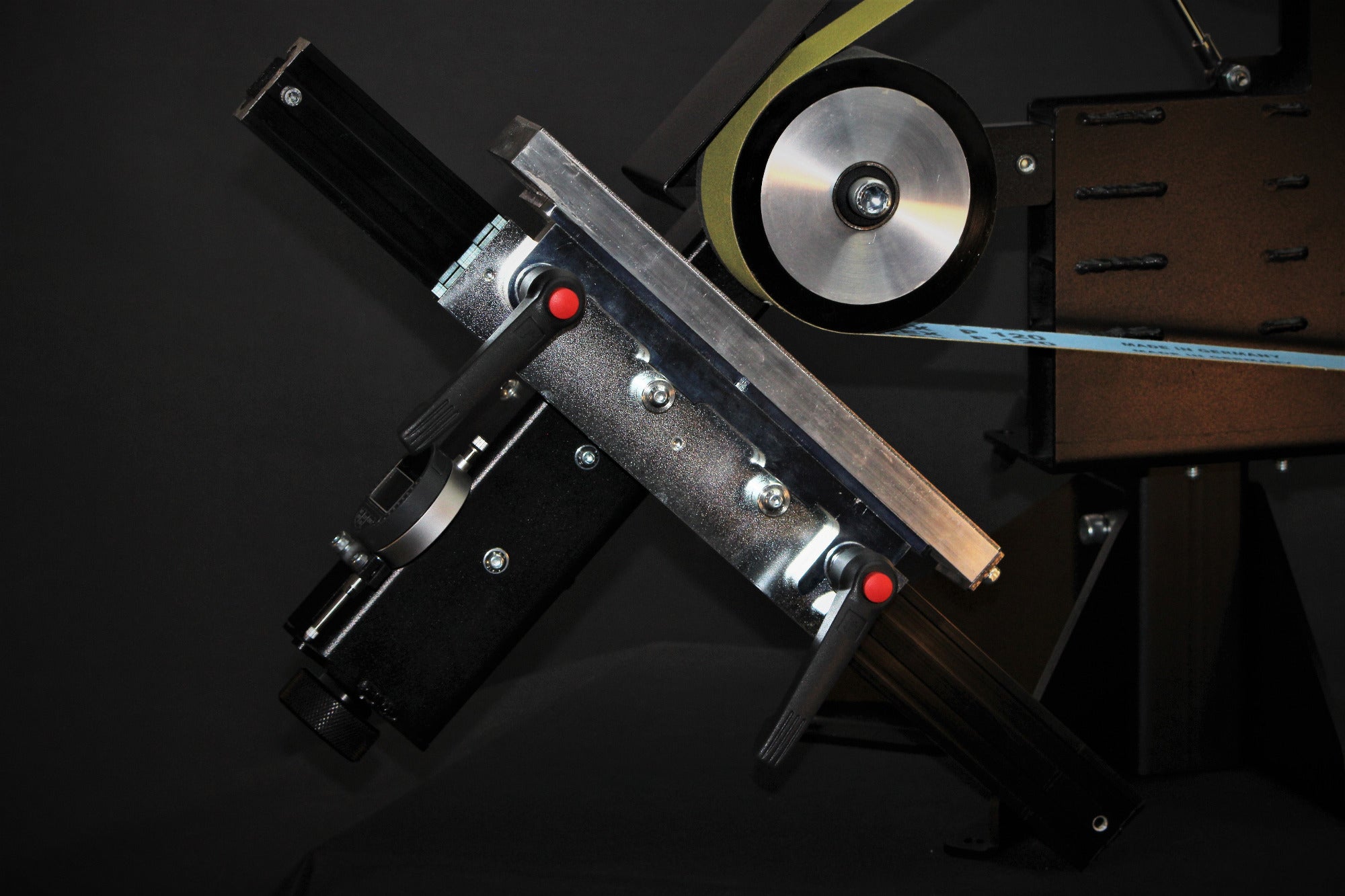

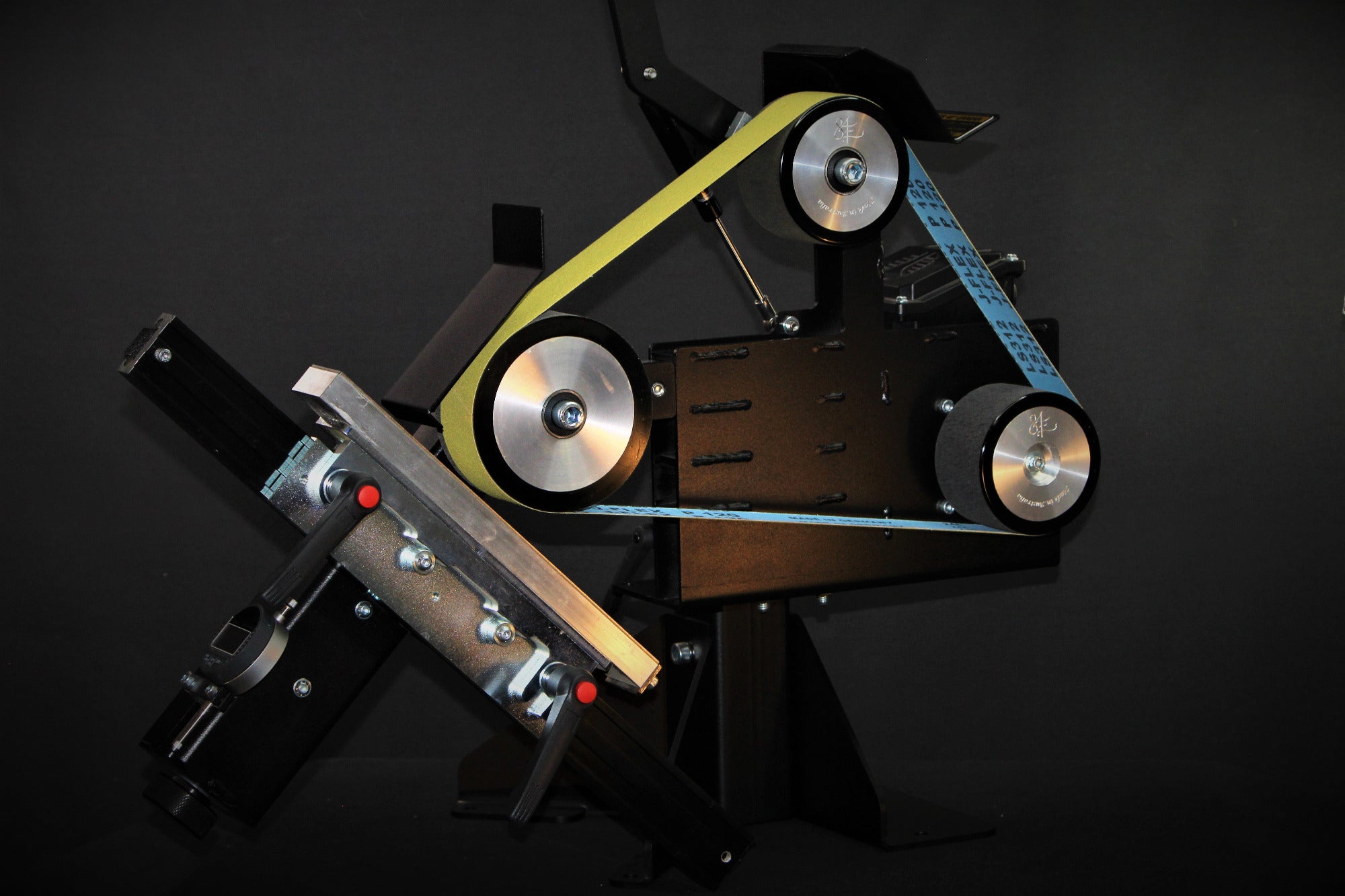

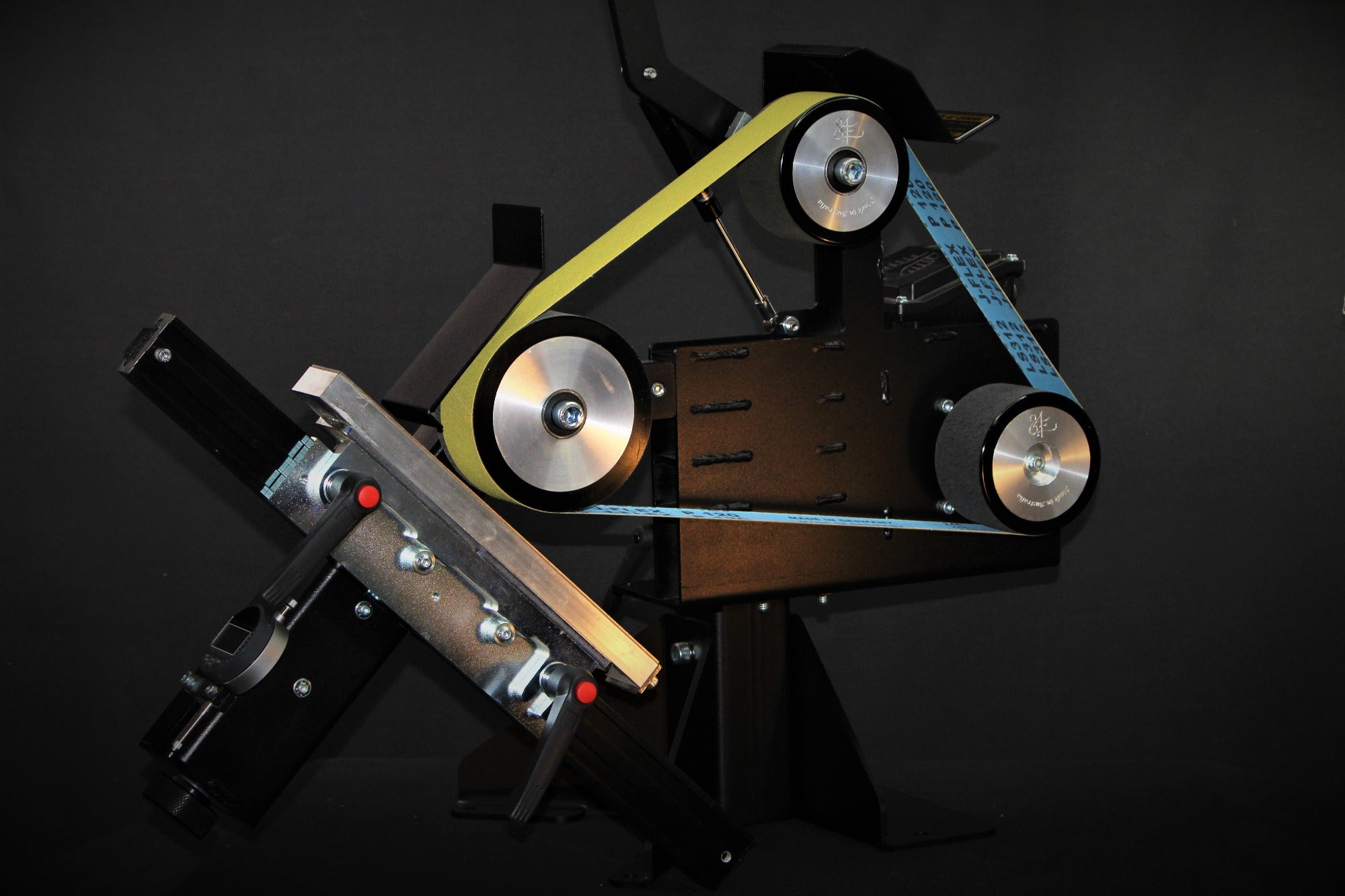

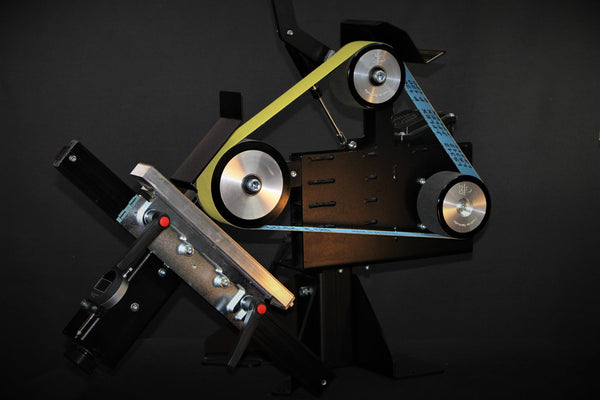

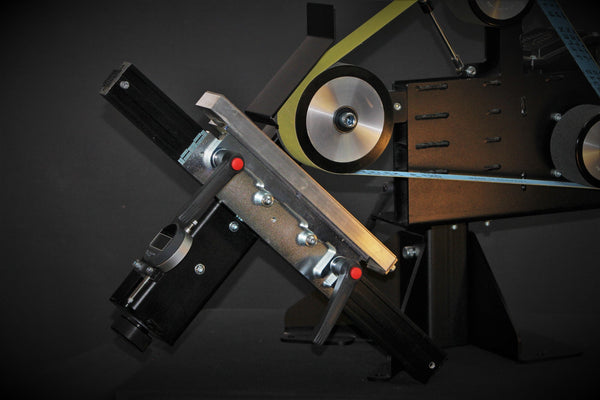

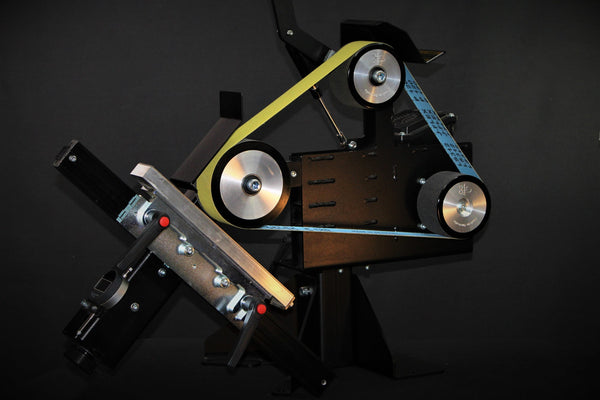

Designed for knife makers and black smiths, the 84 Engineering Strap on Surface Grinder Attachment (SOSGA) makes grinding distal tapers and tapered tangs effortless and repeatable. The level of precision achievable with the tool also makes it great for flattening blanks and billets, removing scale after forging and grinding stock parallel and to a specific thickness (great for making folding knife parts).

Our compact surface grinding attachment is fully compatible with your Shop Mate 48”, Shop Master 72” or Gibson 72” belt grinder using the included SOSGA tooling arm (simply select your grinder option at checkout).

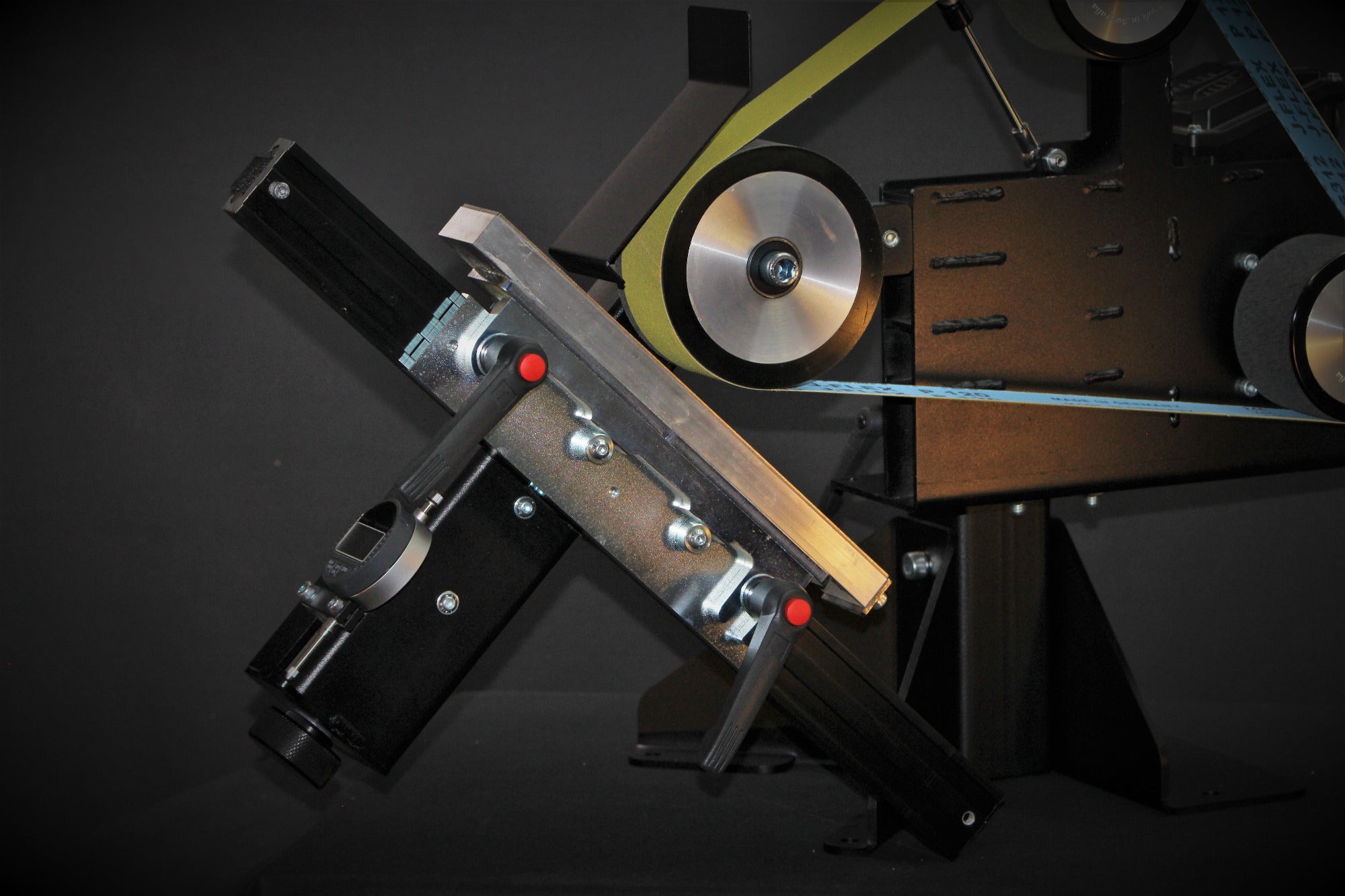

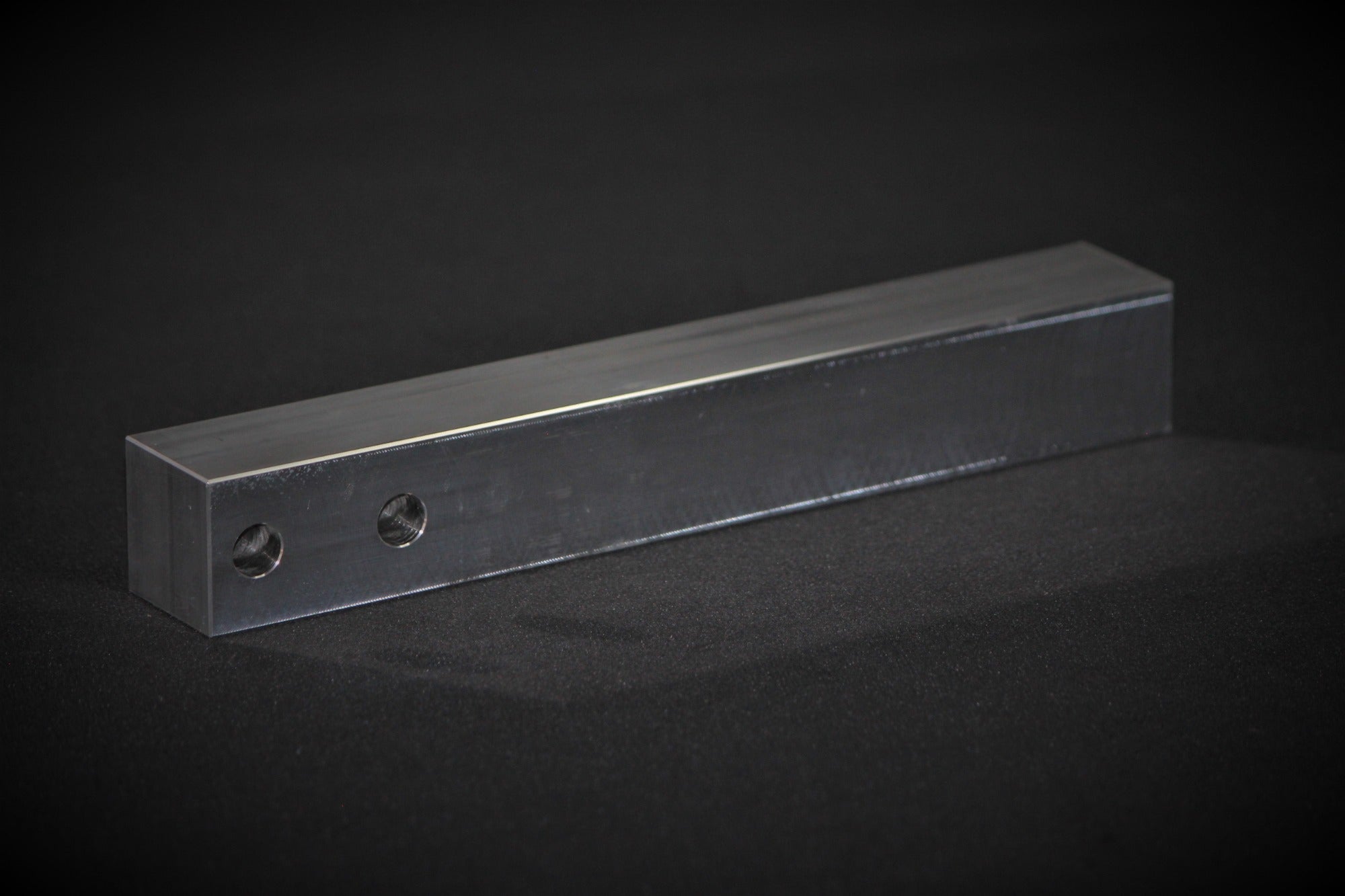

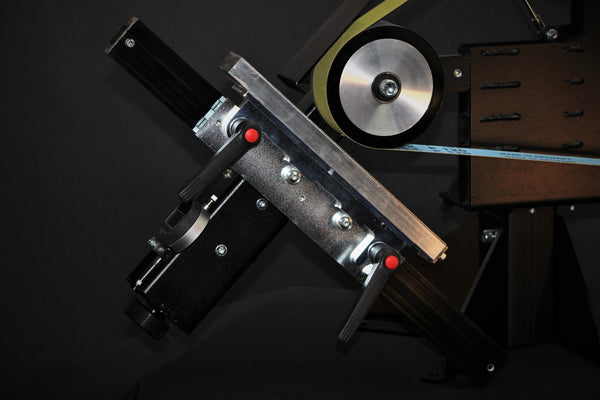

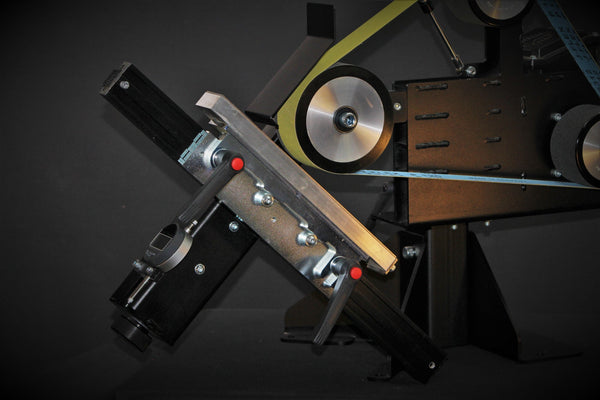

The magnetic surface grinder chuck comprises a CNC machined aluminium billet body, twenty high strength neodymium magnets, an easy-to-clean stainless steel chuck face and an adjustable safety stop at the base of the chuck (we recommend leaving this set 1-2mm above chuck face to stop any chance of work piece coming free).

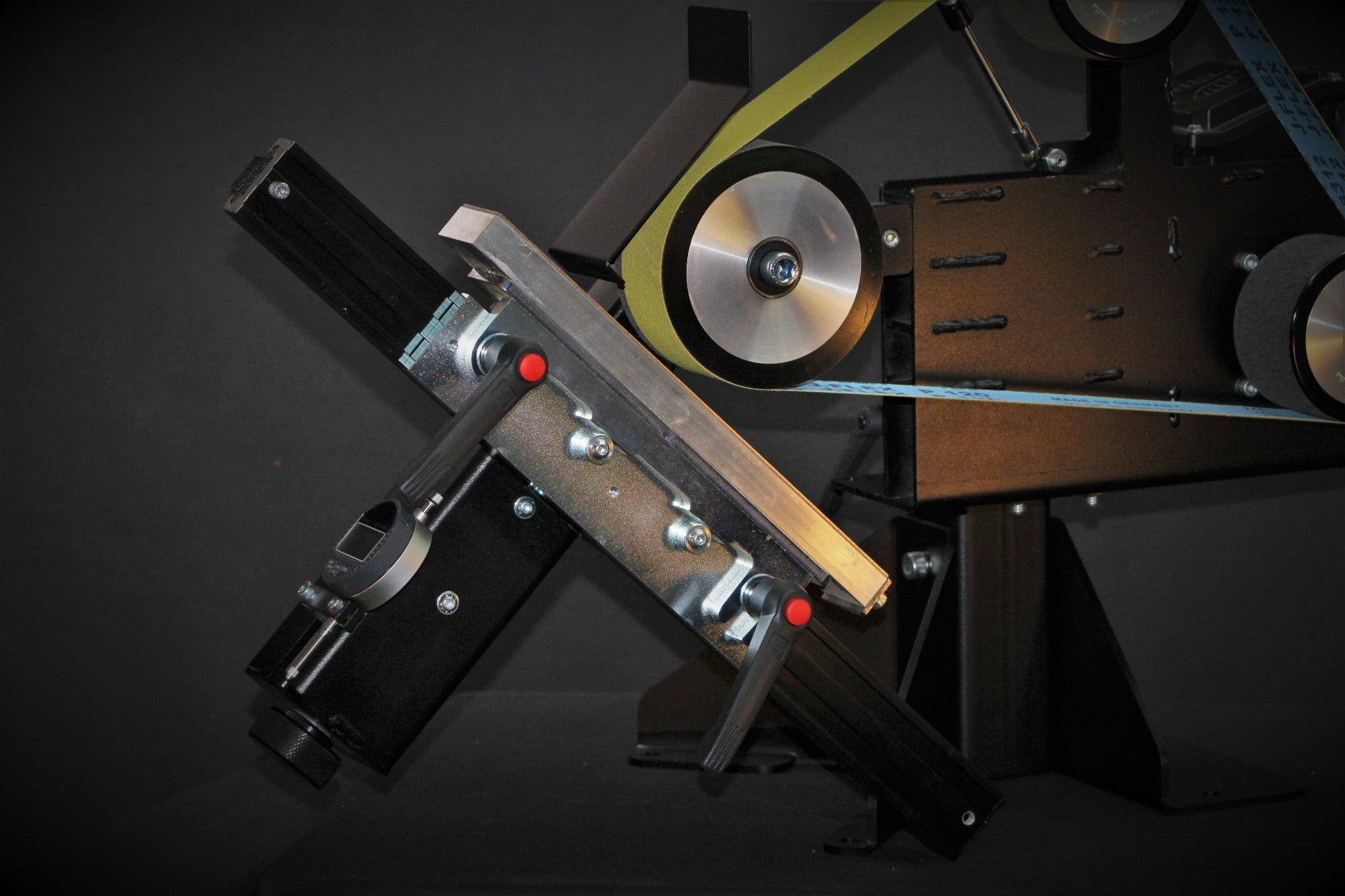

Setting taper angle is achievable simply by using shims – just loosen the locking handles, insert shims, and re-tighten. Included in the SOSGA user manual is a guide on how to calculate correct shim size for different angles and blade lengths.

Depth adjustment is made using the knurled aluminium knob. The fine thread and oversize UHMWPE nut allows for smooth, acute adjustments and will hold in any position without the need for a locking mechanism. The Strap on Surface Grinder includes a dial gauge bracket and base plate, designed to fit any standard 8mm-stem dial gauge, making it easy to achieve precision thicknesses.

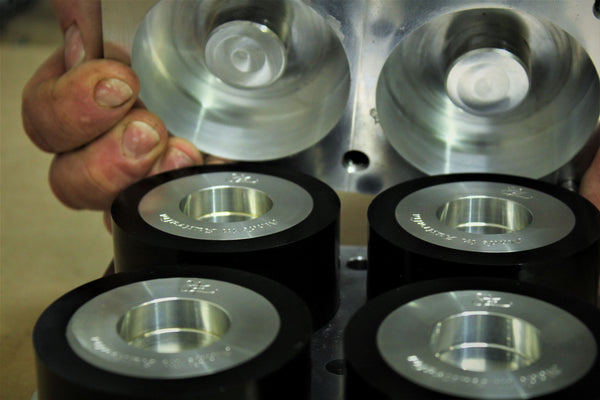

The UHMWPE internal wear components insure tool longevity, smooth operation, and extreme rigidity. High accuracy ball-bearing linear rails are used for the sliding mechanism and the 6061 aluminium contact wheel is coated in a highly durable 90 Shore A polyurethane rubber compound that provides minimal surface distortion whilst having enough flexibility to achieve a great surface finish. The tool is designed to achieve grind accuracy of <50 micron, making it suitable for a variety of precision applications.

-90 Shore A urethane wheel

-6061 Aluminium billet wheel hub

-Premium Timken bearings

-Precision bearing linear rails

-Tool-free adjustment

-<50 micron accuracy

-Industrial hard-wearing powder coated body

-Zinc plated steel components

-UHMWPE internal components for maximum rigidity and longevity

-Spark guard

-Stainless steel chuck

-Bracket for standard dial gauge

-Strap on Surface Grinder Attachment and sliding linear rail

-SOSGA Tooling arm to suit Shop Mate 48 grinder

Our on-line store is open 24/7 and we ship Monday through Friday, excluding some holidays. Orders received for products without shipping restrictions on its product page will ship the following business day when received before 12:00 p.m. AEST. Orders in high demand will have an estimated production time listed on its product page and will ship according to the date listed.

Our SOSGA contact wheels are now coated with highly durable 90 Shore A polyurethane rubber compound that provides minimal surface distortion whilst having enough flexibility to achieve a great surface finish

All components on the SOSGA are designed for maximum accuracy and rigidity. With this machine you will be able to achieve perfectly flat grinds to a tolerance of within 50 microns

SOSGA components are precision CNC machined from Australian manufactured steel or 6061 aluminium for strength and accuracy

DP Custom Knives

Have been a long time customer of 84 Engineering and every product I have purchased has been manufactured incredibly well with very high attention to detail. Customer service has also always been top notch. You will definitely be well looked after here.

Deathrig Fabrication

Amazing Aussie made products - used daily in my workshop. Quality second to none

Cafe Racer Garage

I have been using 84 Engineering belt grinders for many years, it's truly the one tool that gets the most use in my garage building motorcycles, It's one of those tools that you wonder how you ever did without! I highly recommend anyone working with steel have one! Dan - Cafe Race Garage -YouTube

Knife Maker

Our 84 Engineering machine is the best in our workshop and the best we've ever owned. Their service is second to none.

Follow us on social media for the latest news, deals and updates

© 2026, 84 Engineering Powered by Shopify